Plastic Engineering for Consumables

Engineered to meet rigorous standards

With deep expertise and strict process control, we deliver consumable solutions that align with the highest industry benchmarks.

Seamless Compliance

We provide medical consumables fully compliant with industry standards, ensuring a smooth path to market.

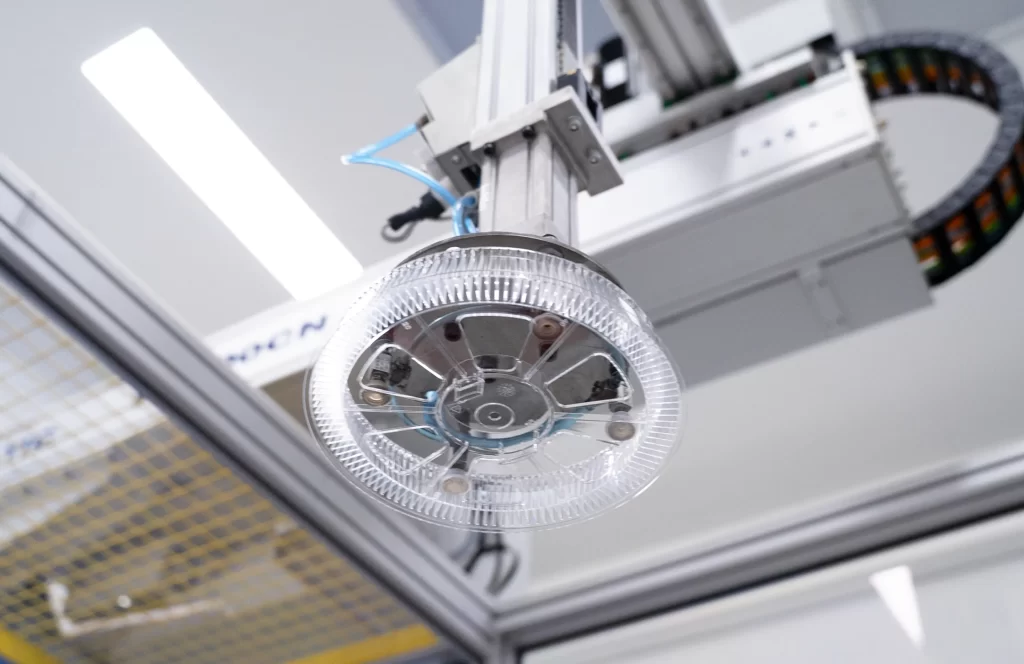

Efficient Assembly

Precision, speed, and reliability, our automated processes ensure high-quality medical consumables with full regulatory compliance.

Continuous Supply

Maintain seamless operations with an uninterrupted and reliable supply of medical consumables, ensuring no delays or shortages.

Consumables for Medical

and Laboratory

We produce medical and laboratory consumables that streamline your processes, without compromising optimised performance and full compliance with medical industry standards.

Single-Use

Components

Precision-moulded fluid connectors, valve systems, single-use manifolds.

Labware &

Reaction

Pipette tips, PCR plates, reagent trays, centrifuge tubes.

Packaging &

Reservoirs

Sealing caps, barrier stoppers, fluid reservoirs, protective housings.

Syringes &

Fluids

High-precision barrels, plungers, and caps for manual and auto-injector systems.

Integrated Plastic Solutions

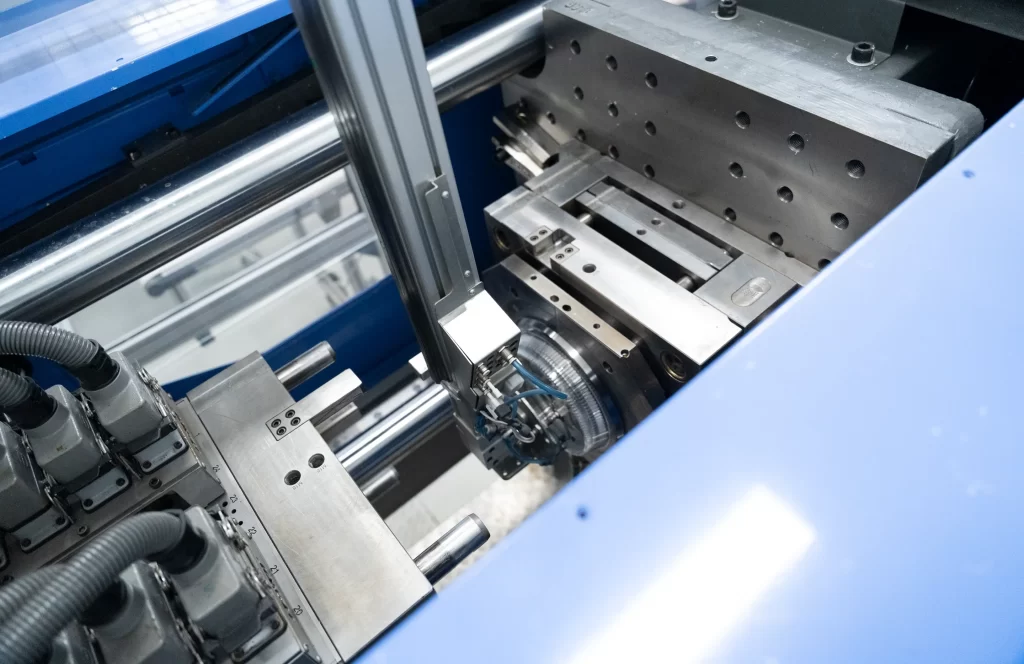

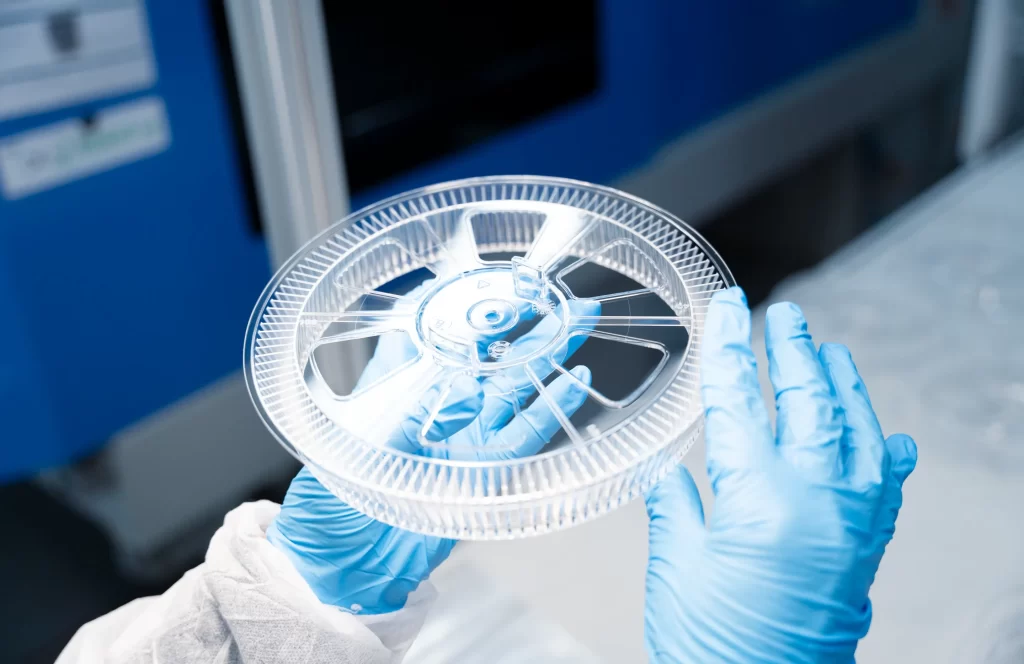

Clean Room ISO 7

for Injection Moulding

Maintaining strict safety conditions, because in healthcare, precision saves lives. Our

ISO 7 Clean Room provides air cleanliness levels of up to 10,000 particles (≥0.5µm) per

cubic foot and a minimum of 60 air changes per hour.

Portfolio & Case Studies

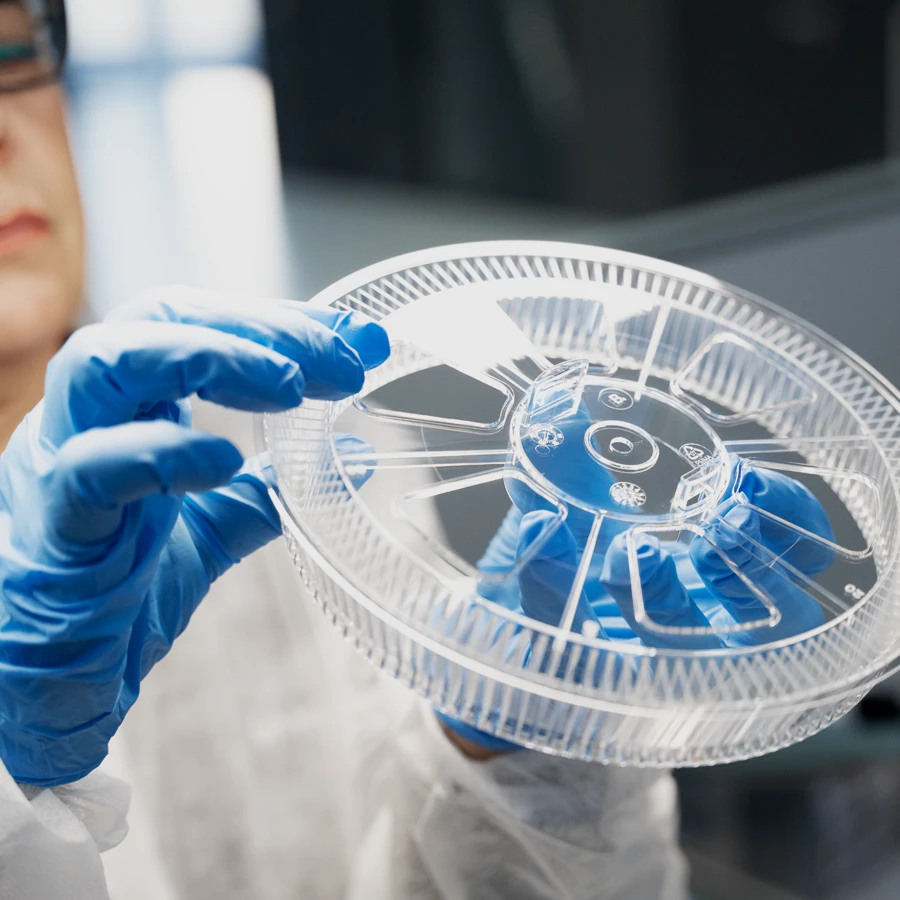

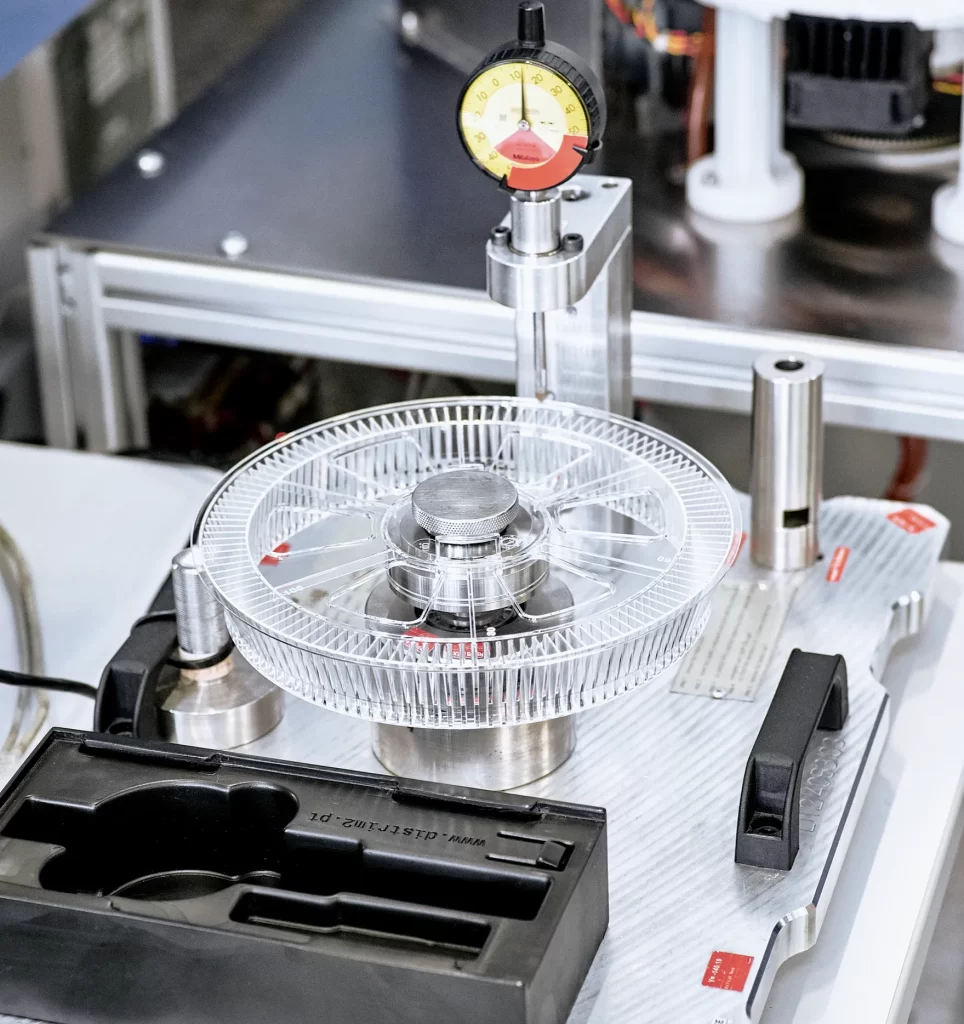

Sample Rotor for Biochemistry Analysers BA200 & BA400

PMMA - Injection

Client: Biosystems

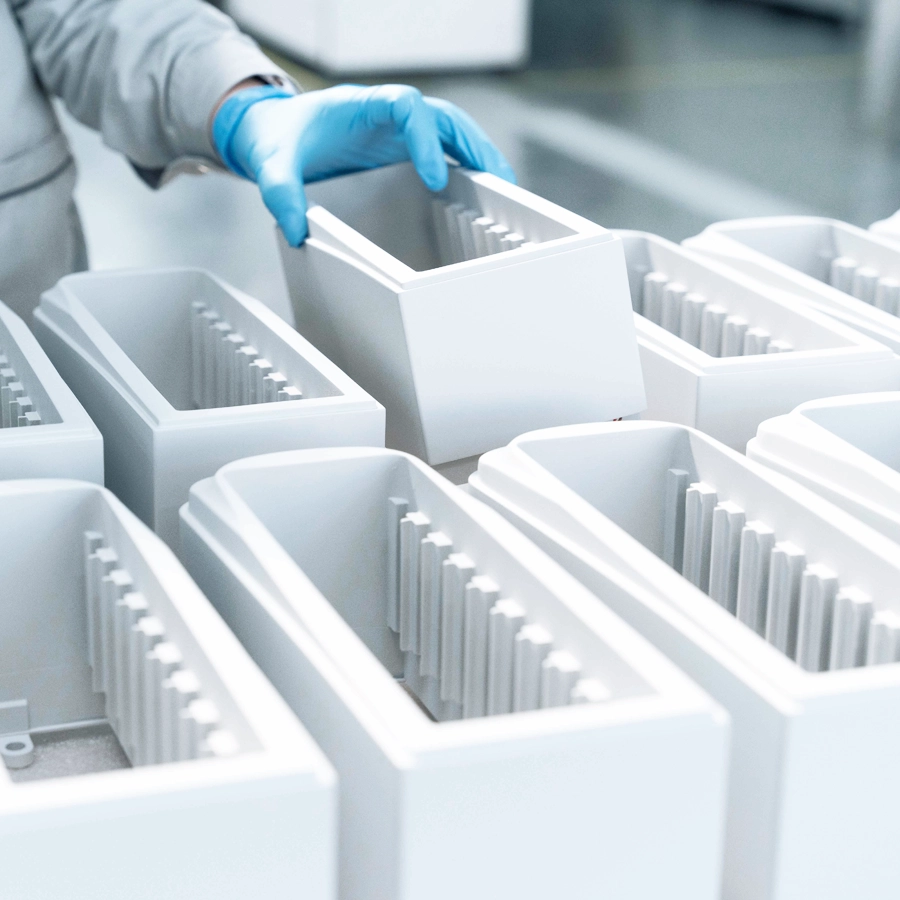

Disposable Containers for bio samples analyses

Injection & Assembly

Client: Biosystems

Reagent Bottle for Biochemistry Analysers BA200 & BA400

New Product Development, Design Engineering, Mould Making, Production and Assembly

Client: Biosystems

End-to-End Manufacturing Partner

for Certified Medical Products

We deliver fully integrated engineering, mould making, and ISO 13485-certified injection moulding, with robust validation and cleanroom capabilities tailored to the demands of regulated medical markets.

Full Product Lifecycle Integration

From concept to validated production, we streamline every step to reduce risk and accelerate readiness.

Regulatory-Compliant and Validated Manufacturing

Our manufacturing model is built on strict process validation (DQ, IQ, OQ, PQ), risk mitigation (DOE, FMEA), and cleanroom ISO 7 production, ensuring that every product meets global regulatory requirements and quality assurance standards for medical devices.

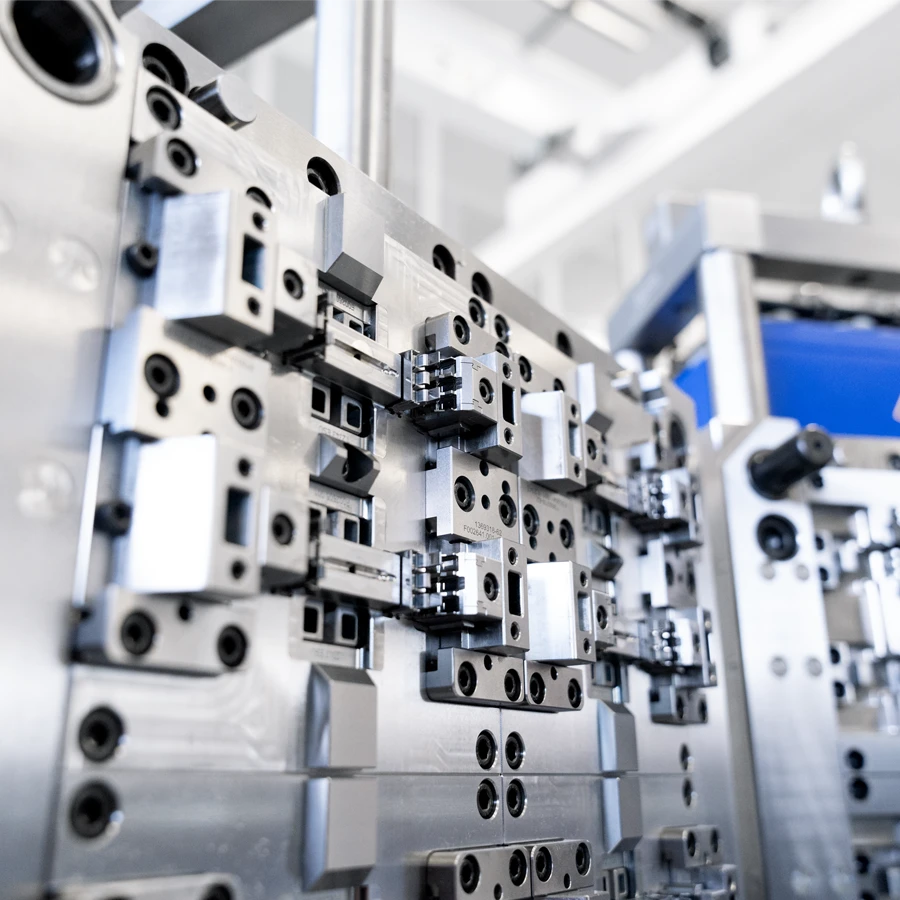

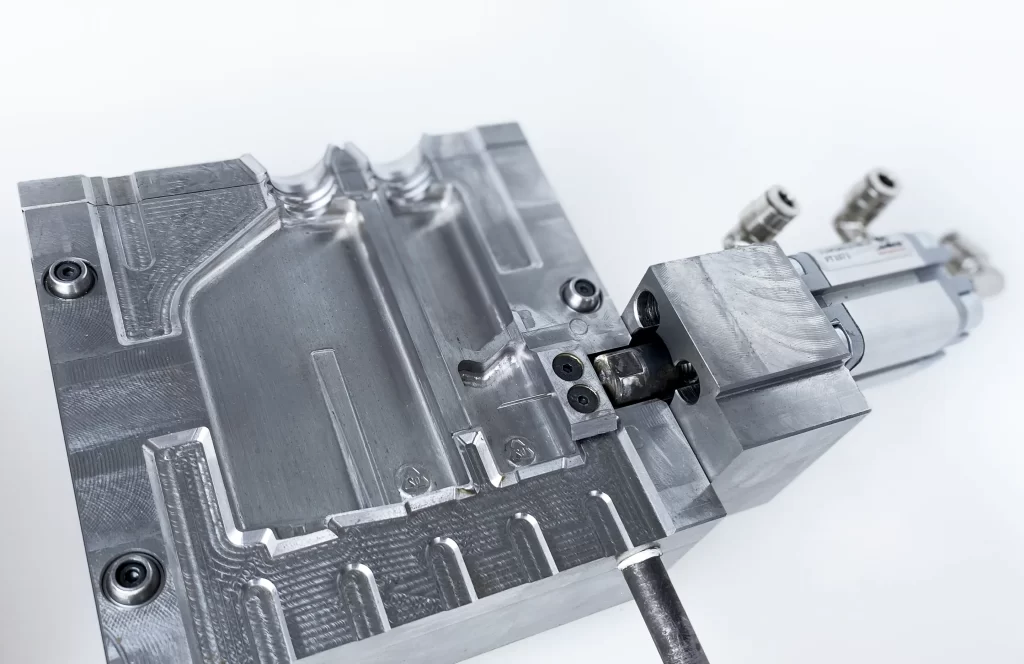

Advanced Mould Making and Injection Expertise

With decades of precision tooling and injection moulding experience, we deliver complex, high-tolerance components ready for scalable medical production. Our in-house capabilities ensure robust tool performance, dimensional stability, and repeatability in high-volume output.

Balanced Costs and Value through Design Optimisation

We apply DFM, DTC, DFA, and DTV principles to optimise manufacturability and cost without compromising quality.

Engineering with Simulation-Driven Decision Making

CAD, FEA, CFD, and Moldflow tools drive early-stage decisions that reduce iterations and improve long-term yield.