From Functional Prototypes to Final-Use Parts

Rapid Manufacturing for Early Medical Validation

Validate your medical device early with precise prototypes designed to meet strict regulatory standards. Make confident decisions with prototyping that allows you to perfect your product, reduce costs and accelerate time-to-market.

Multidisciplinary

Team

Your focus is our focus. We bring together experts in design, engineering, and manufacturing to deliver solutions where innovation and production align, ensuring efficiency at every stage.

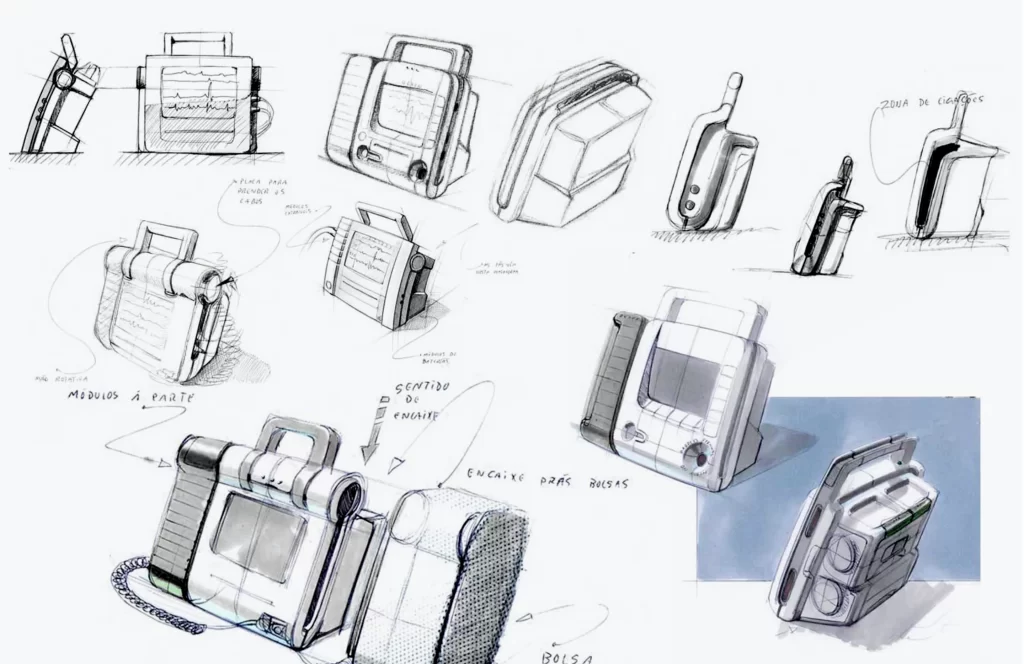

Prototyping for better

time-to-market

Use prototypes to test and validate your product, accelerating time-to-market. Prototyping allows you to fine-tune functionality and optimise the performance of your medical device.

Small-scale

production

We can quickly test and validate your product with solutions tailored to your case and with a reduced upfront investment.

High-volume

production

We produce in high volumes, maintaining consistent quality and efficiency, thus guaranteeing cost-effective production and a faster time-to-market for large-scale orders.

Rapid Manufacturing for Medical, Lab & Healthcare

From 1 to 25 parts. Prototyping & Rapid Manufacturing

Our prototyping and rapid manufacturing solutions cater to diverse needs, whether you require a single prototype for testing or a small production run of up to 25 parts. This flexibility accelerates development, ensures precise validation, and helps you achieve your project’s goals.

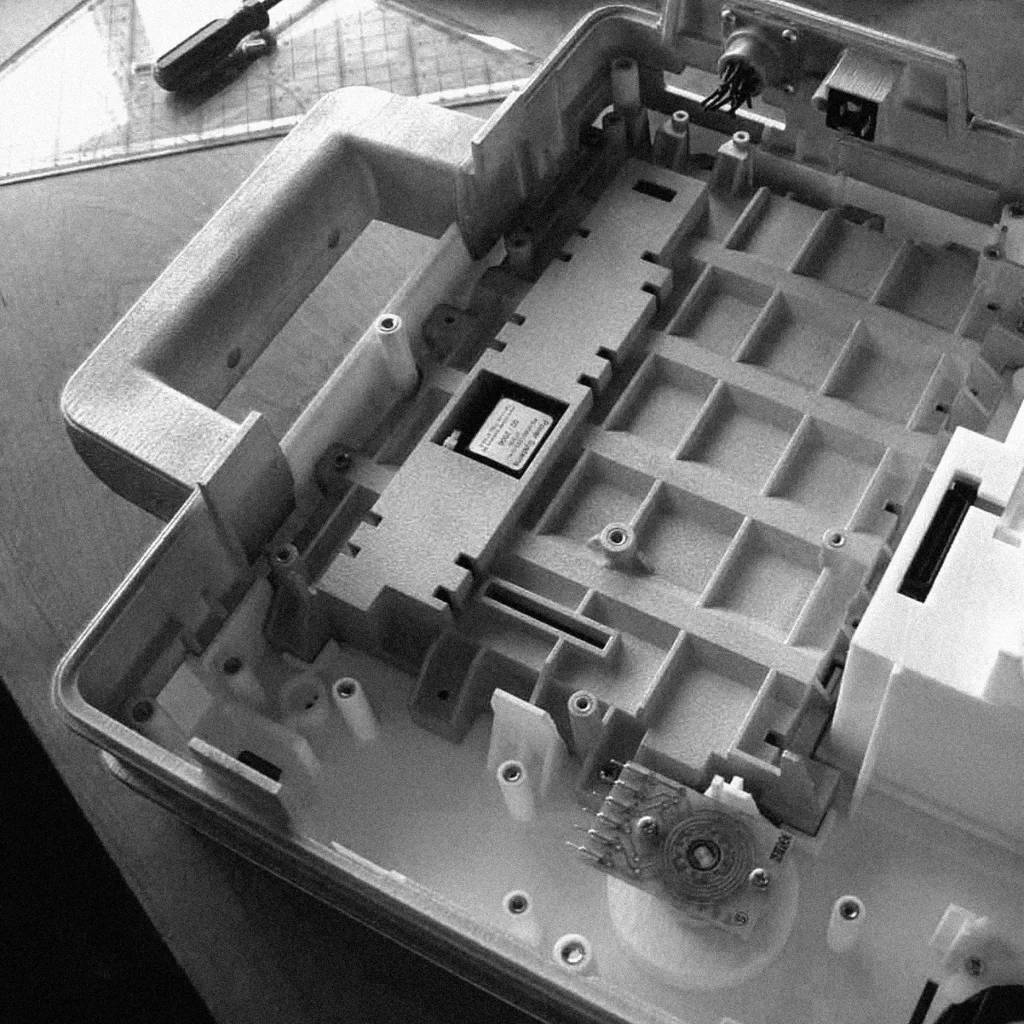

Precision Manufacturing for Rapid Development

We combine advanced manufacturing techniques such as 3D printing and vacuum casting to accelerate the development of medical products. Our process ensures flexibility, reduced costs, and faster access to market without compromising quality.

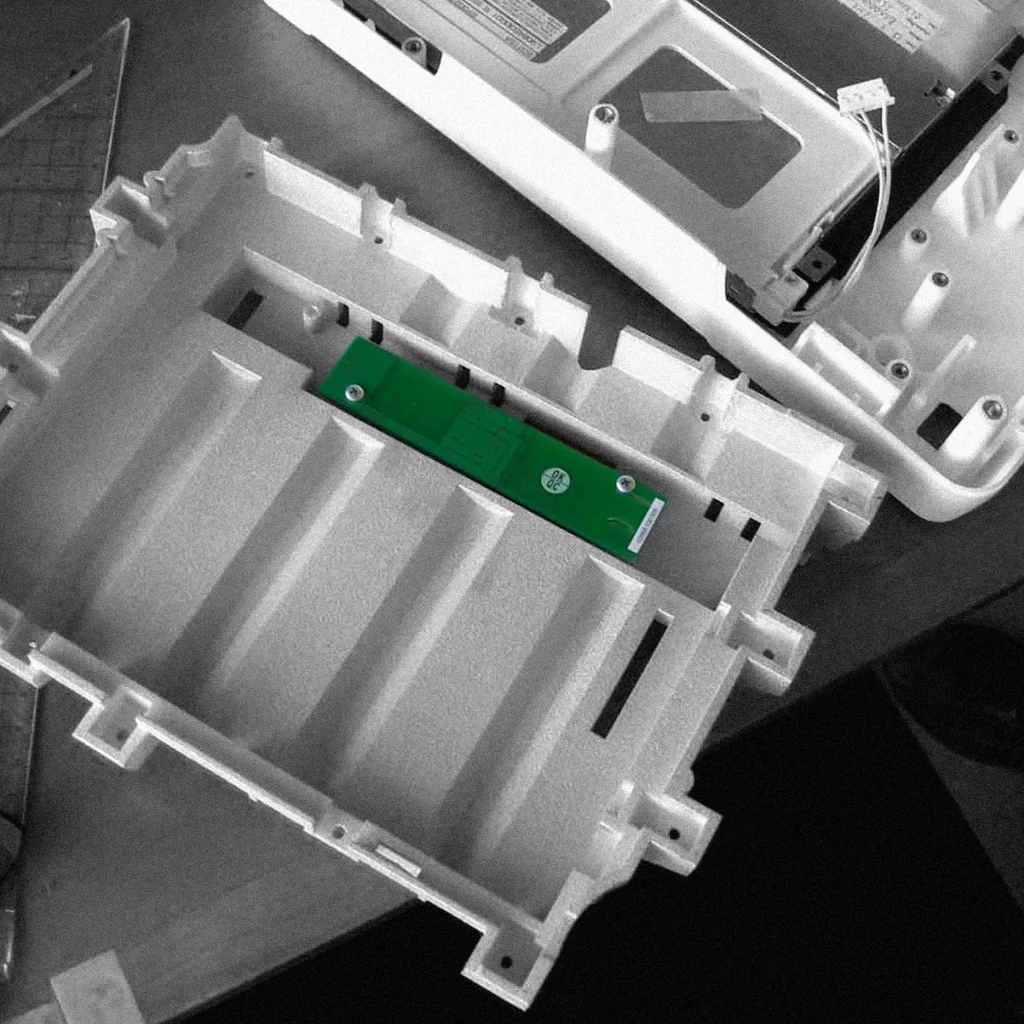

Low Initial Investment

Advanced manufacturing techniques such as 3D printing and vacuum casting eliminate costly tooling, making them ideal for low-volume medical device production, prototype validation, and early-stage clinical trials.

Short Lead Times

By leveraging rapid prototyping and agile production methods, manufacturing lead times are significantly reduced compared to traditional. This allows for a faster transition from concept to commercialisation, expediting access to life-saving medical technologies.

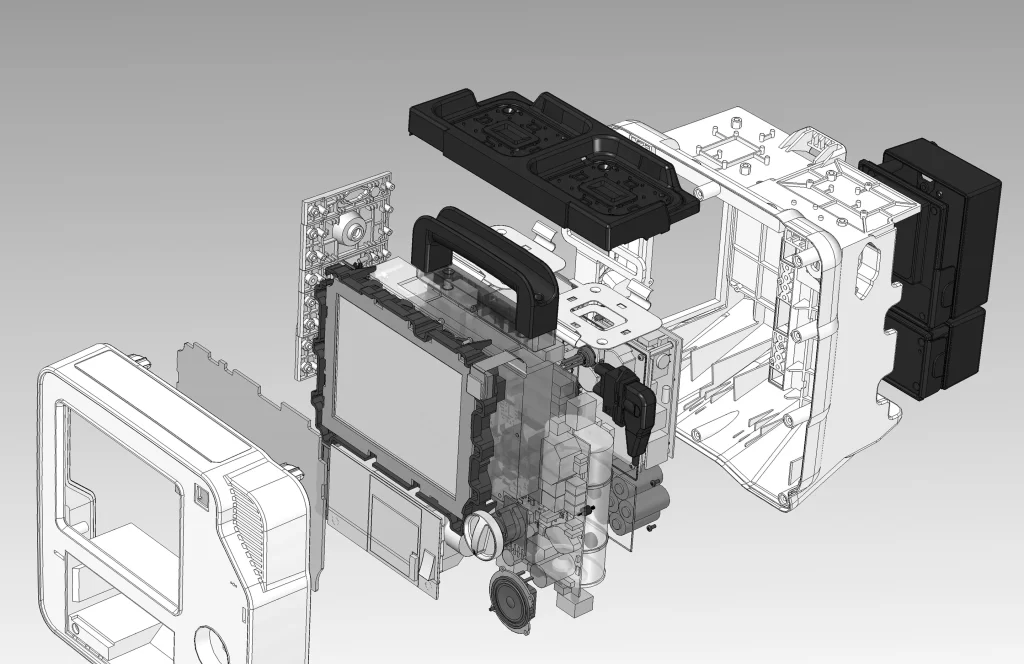

Design Flexibility

These cutting-edge processes enable the production of highly customised components with complex geometries that would be challenging to achieve with conventional manufacturing. This flexibility supports iterative design improvements without the added costs of retooling.

Customisation and Complexity

The ability to produce components in diverse biocompatible materials, with precise finishes and intricate designs, removes the limitations of conventional fabrication. This approach is particularly advantageous for personalised medical solutions and small-scale production needs.

High-Quality Low-Volume Manufacturing

3D printing and vacuum casting allow for the production of small batches of highly detailed and precise medical components. These methods are essential for niche markets that require limited quantities of end-use parts, maintaining uncompromised quality and performance.