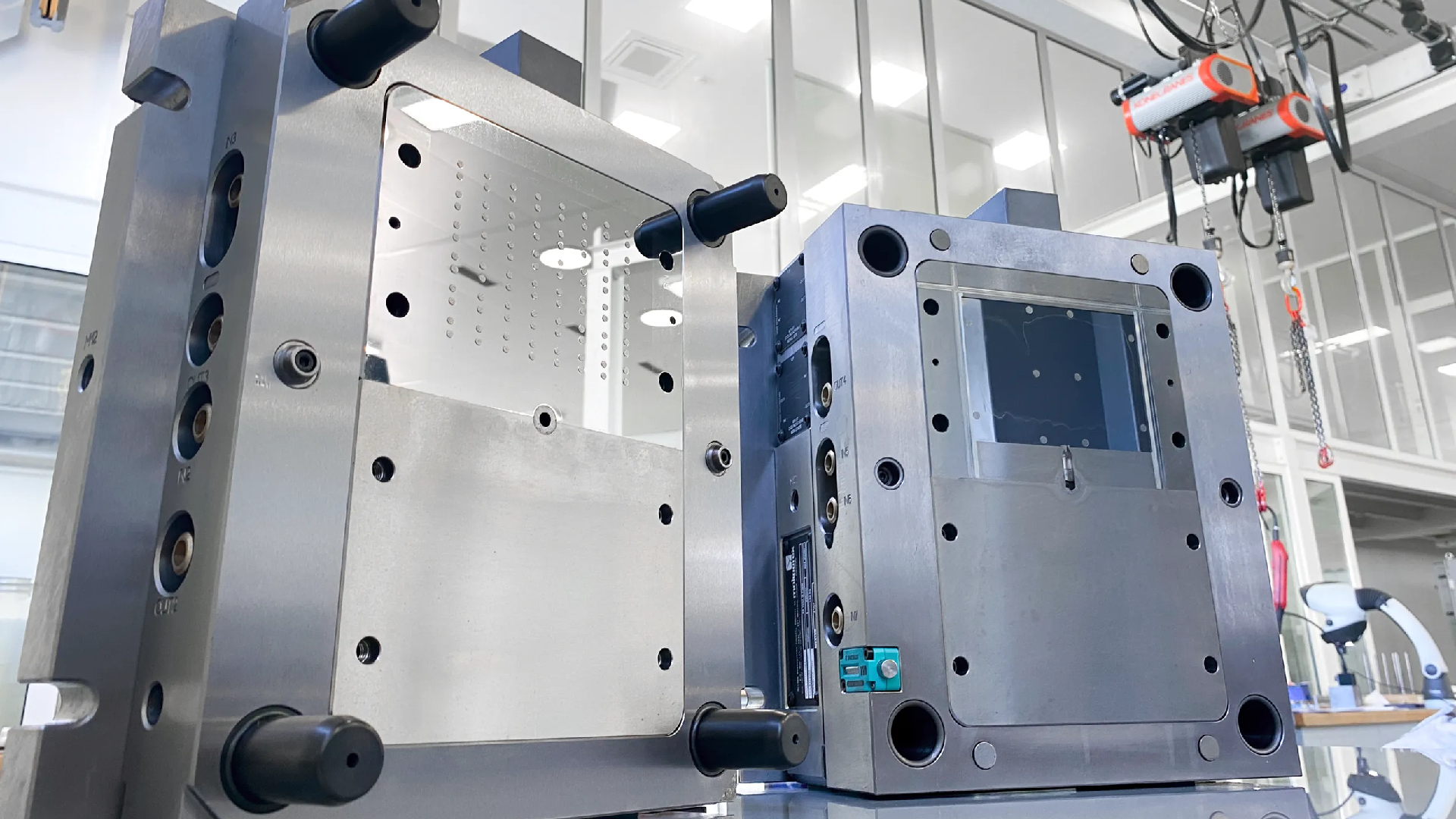

High-Precision Mould Making for Medical Devices

Tooling Designed for Regulatory Performance

We engineer every mould to meet the traceability, compliance, and performance demands of ISO 13485 environments. From single-cavity validations to high-output serial runs, our tools are built for process accuracy, cleanroom readiness, and full regulatory alignment.

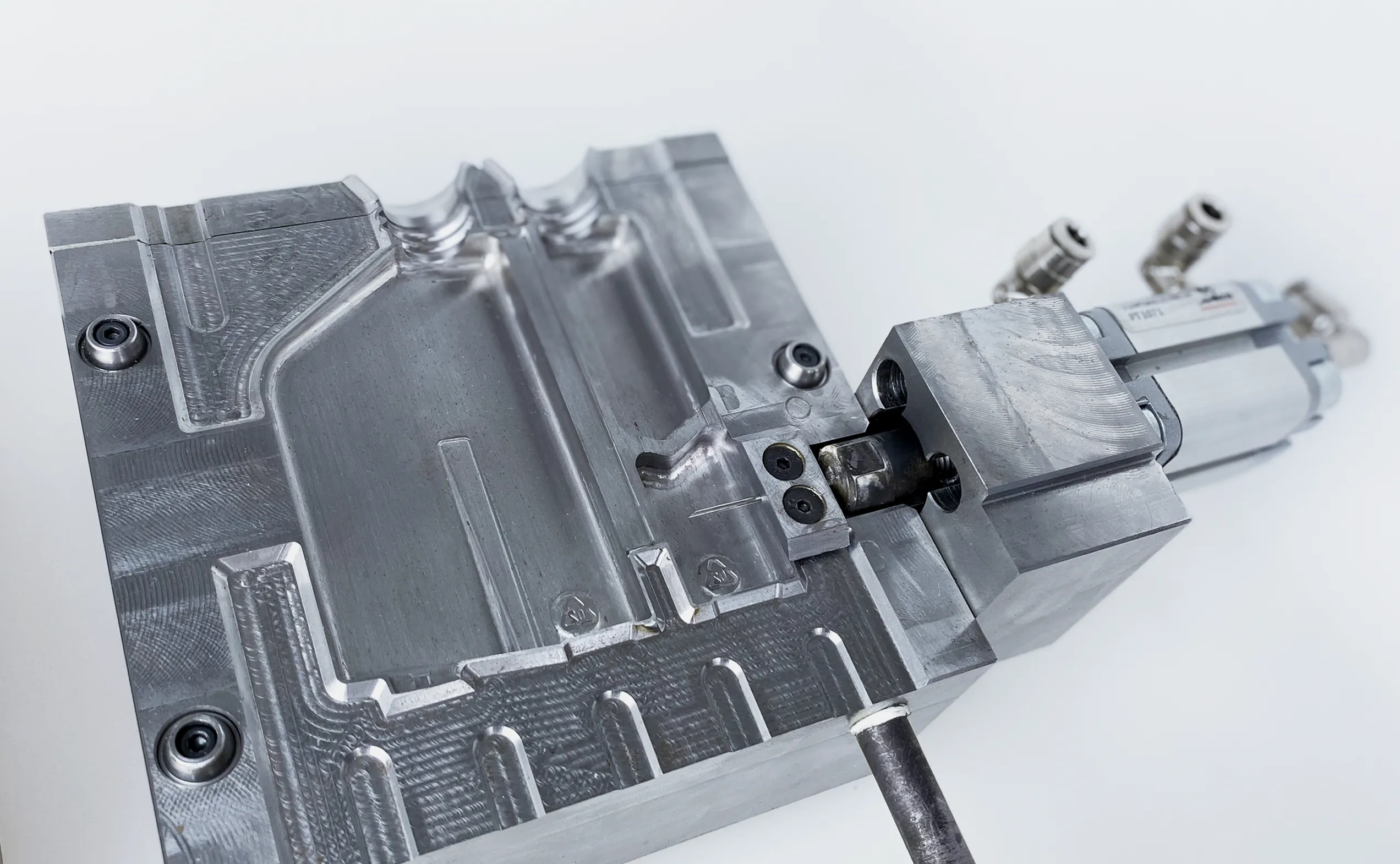

Pilot & Pre-Series Tooling

Single and low-cavity tools built for first-shot accuracy, IQ/OQ/PQ compatibility, and clinical-grade material testing. All tooling is manufactured in climate-controlled conditions with full ISIR, CPK analysis, and documentation to support cleanroom transfer and design freeze.

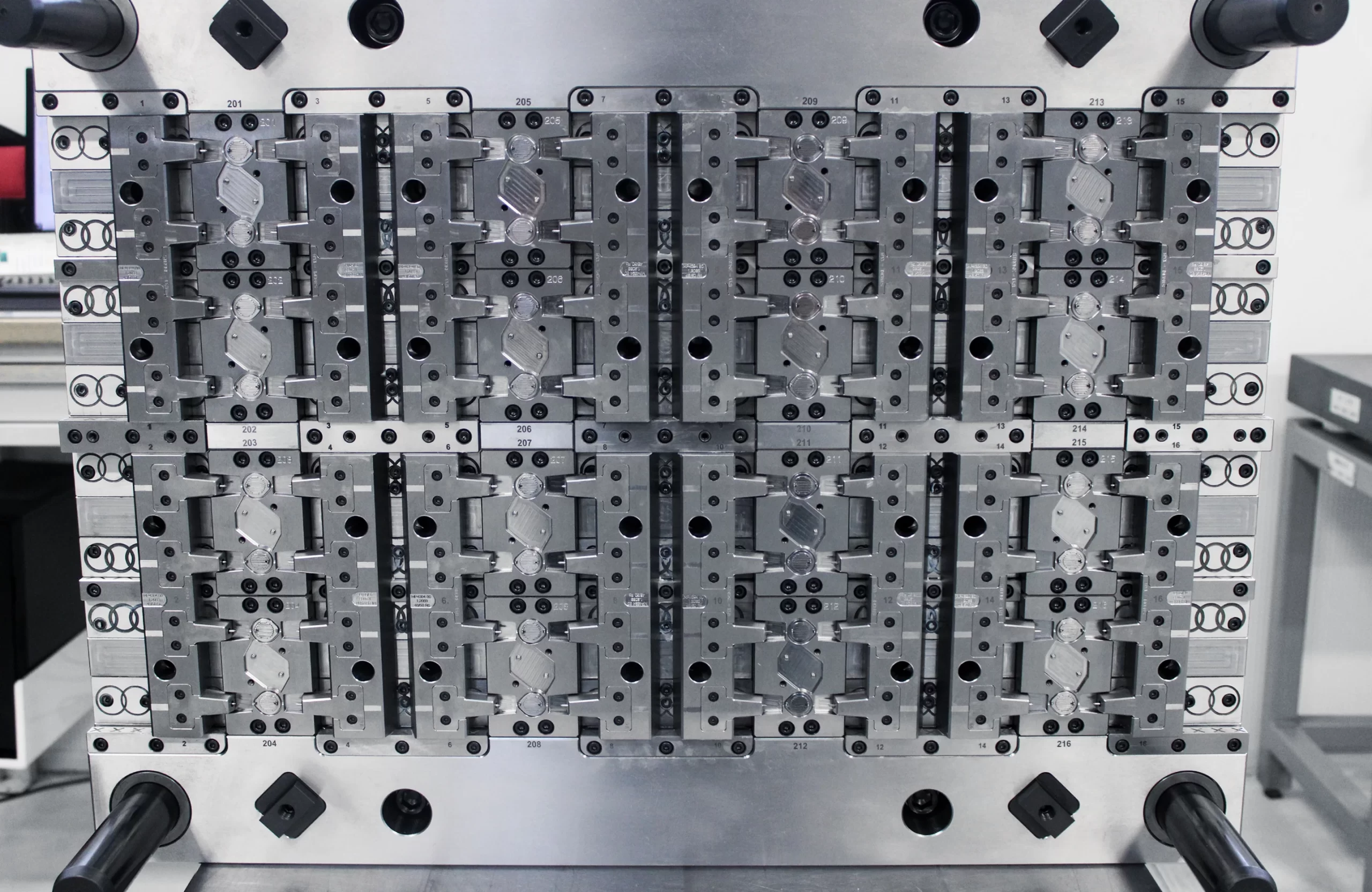

Serial Tooling

Our serial tools are engineered for high repeatability and consistent performance in cleanroom environments. With hardened stainless steel construction, efficient thermal management, and optimised ejection systems, they reduce maintenance needs and downtime. High-precision cavity balancing, process capability analysis, and interchangable components support reliable inspection reports and long-term production stability.

High-Precision Tooling with Modular Interchangeability

End-to-End Mould Expertise for Regulated Markets

We support medtech, pharma, and biotech innovators with precision-engineered tooling workflows, from concept validation to serial production. Our integrated engineering, tooling, and qualification systems are built to meet ISO 13485 requirements, cleanroom compatibility, and validation traceability.

Engineering

Support

39 years in mould making, DFM/DFMA approach, Design freeze validation

Mould

Design

CAD/CAM for tight tolerances, Modular, interchangeable layouts, Downtime-minimised builds

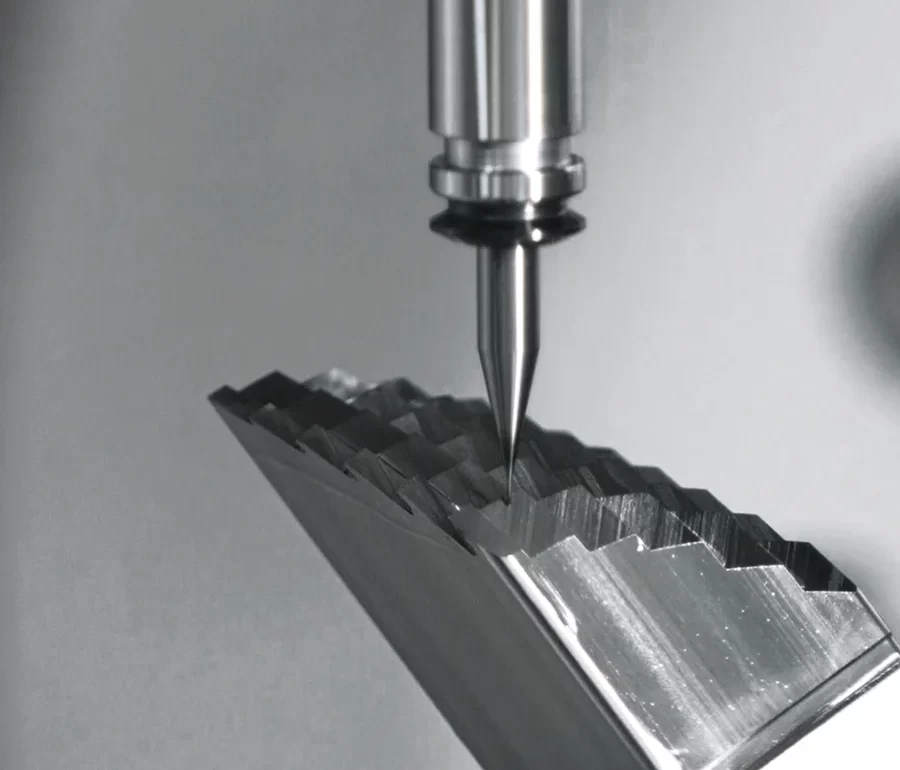

Mould

Manufacturing

Micro-milling and 5-axis EDM, Cavity balancing and fast cycles, Hardened steel for longevity

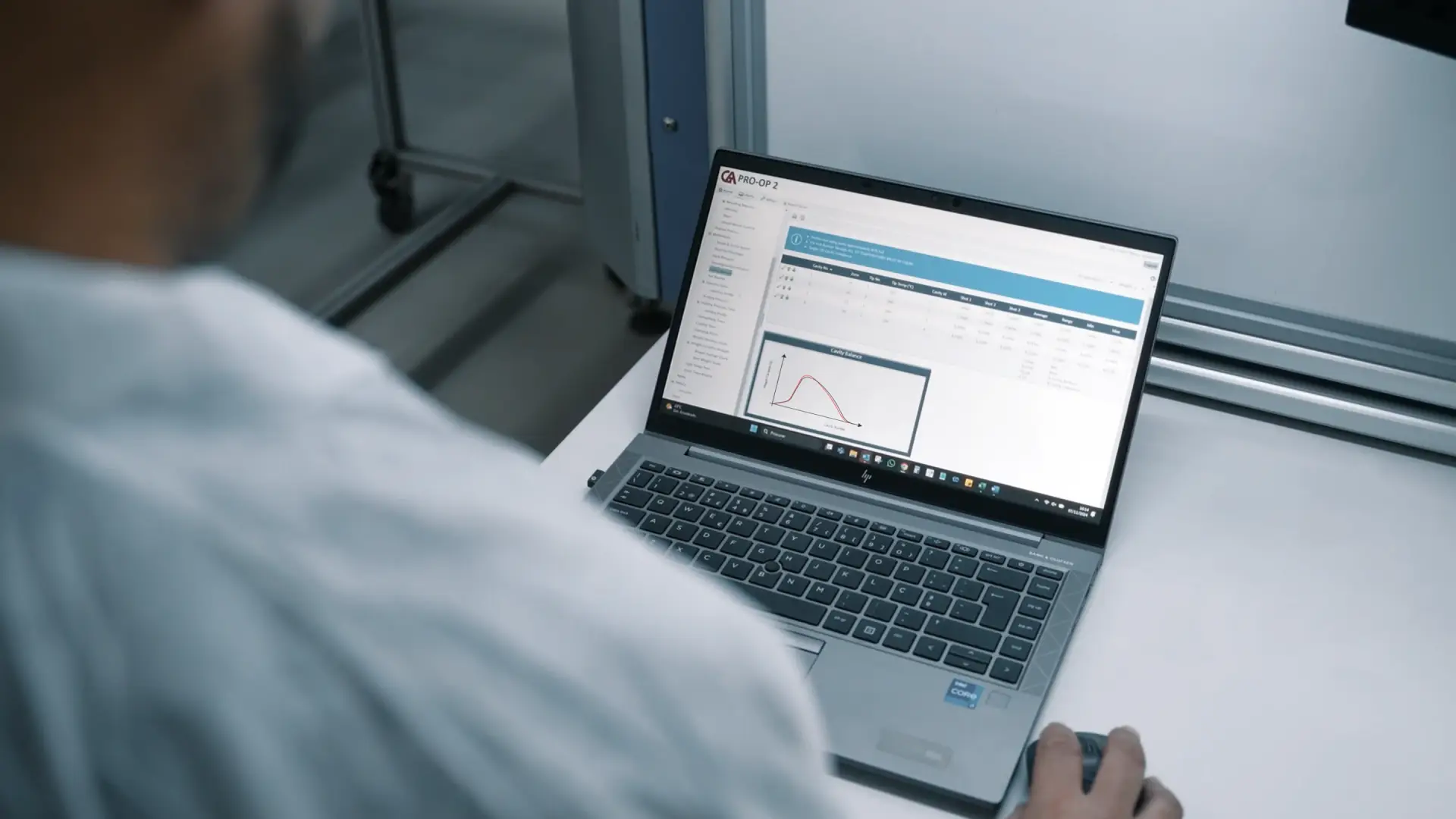

Mould

Qualification

IQ/OQ/PQ ready, ISIR, CPK, SPC reporting, In-house Try-Out Center

Advanced Moulding Techniques

for Functional Integration

We engineer moulds with a focus that goes beyond geometry, optimised for functionality, reduced assembly, and full regulatory compliance. From overmoulding metal inserts to integrating labelling in the mould, our tooling ensures final-part performance straight from the injection moulding machine.

Scientific Moulding Approach

Our tooling and moulding setups follow a scientific approach, using in-mould sensors to monitor cavity temperature and pressure, optimise gate freeze timing, and control each phase of the injection process. This ensures precision, consistency, regulatory compliance, and supports full traceability.

In-Mould Assembly & Labelling

We engineer moulds that integrate subcomponents and labels directly during injection moulding. This eliminates secondary steps, enhances part cleanliness, and supports traceability in high-volume manufacturing environments.

Metal Overmoulding &

Reel-to-Reel

To ensure precise placement and secure adhesion of metal components, we engineer inserts and runner layouts with accuracy in mind. Thermal and mechanical bonding is achieved with minimal shift tolerance, ensuring consistent encapsulation performance across production.

Integrated Engineering & Tooling Value

Our integrated approach to engineering and tooling enables the creation of medical-grade moulds that meet the highest standards of precision, hygiene, and product lifecycle reliability.

Engineering-Led Product Development

Our DFM/DFA approach integrates material selection, tolerance control, and tool readiness from day one, reducing design loops and accelerating validation.

Single-Source Technical Partner

We manage the entire lifecycle in-house: engineering, toolmaking, sampling, and injection. This vertical integration ensures traceability and repeatable quality.

Advanced Moulding Technologies

From metal overmoulding and 2K tools to in-mould assembly and smart part integration, we build functional performance directly into the mould.

Dedicated Project Cells

Each program is handled by a focused, cross-functional team with tooling, metrology, and process engineering expertise, ensuring on-time delivery and compliance readiness.

Built for Lifecycle Scale-Up

Whether starting with a single-cavity pilot or moving to 128 cavity high-output systems, our scalable tooling ensures platform consistency, ease of maintenance, and cleanroom alignment.