New Product Development focused on Function and Feasibility

New Product Development with Manufacturing in Mind

Our industrial product development follows a structured, production-oriented process. From concept development and functional design to prototyping and manufacturability analysis, each stage is aligned with engineering and manufacturing requirements, ensuring your product is ready for efficient and scalable production.

Design &

Engineering

We merge design innovation with engineering expertise to transform ideas into market-ready products. Using state-of-the-art technology and rigorous testing, we deliver tailored solutions that exceed industry standards.

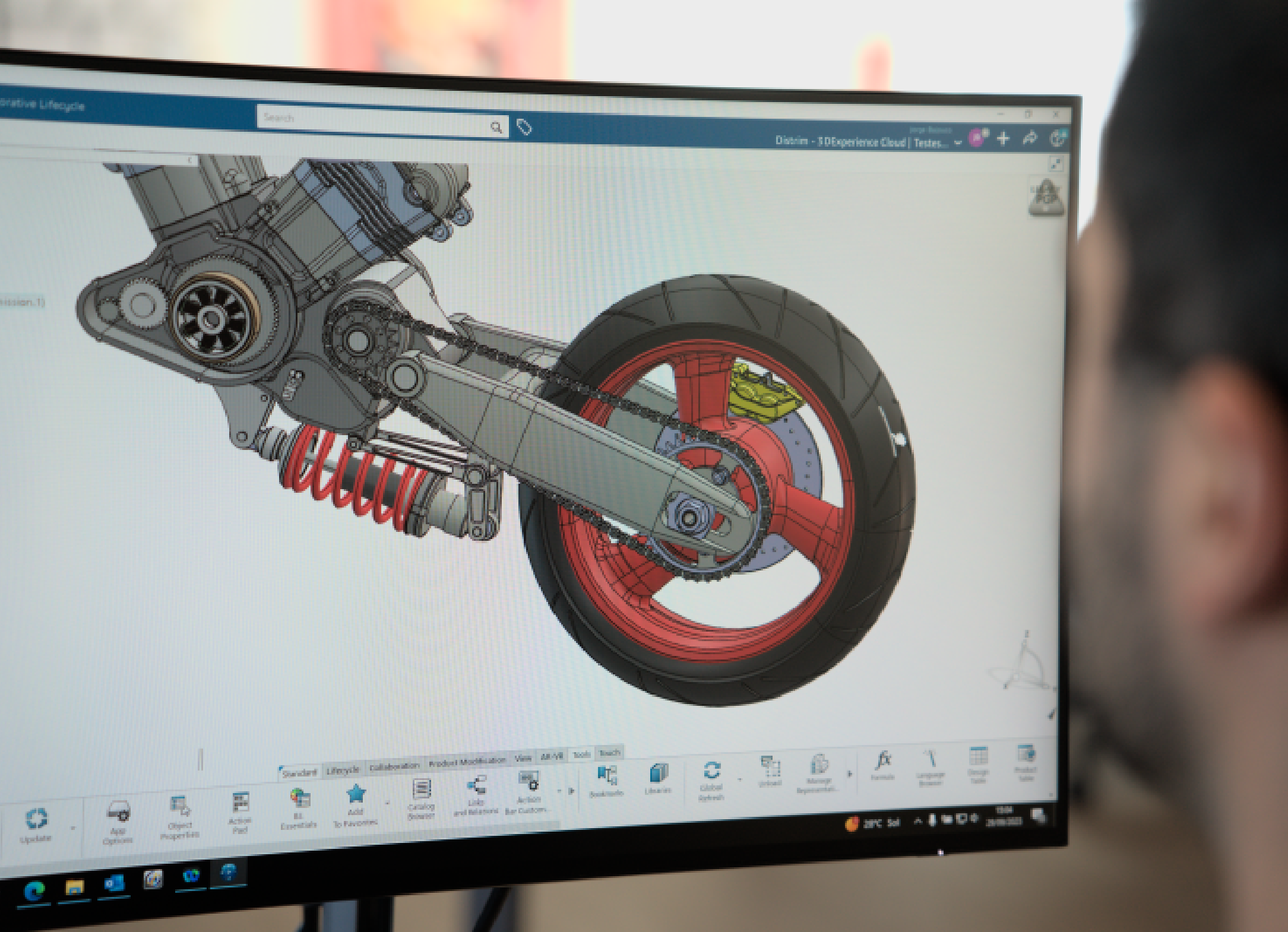

CAD 3D &

Prototyping

Leveraging advanced simulation tools, we refine and validate designs early in the development process. This proactive approach minimises risks, reduces time to market, and ensures peak product performance.

From Design Concept to Industrial Production

Industry-Focused

Design

We create designs tailored to your production technologies and preferred manufacturing methods, ensuring your product aligns with your goals.

Development and

Engineering

We design each part with a production process in mind, reducing the need for changes and streamlining product development from start to finish.

Collaborative

Development

From concept to delivery, we work closely with you to shape a product that aligns with your vision and excels in your market.

Testing &

Validation

With in-house rapid prototyping, we test concepts quickly, validating functionality and aesthetics to ensure your product meets exact expectations.

Creating value from the start with manufacturing in mind

New Product Development: From Concept to Validation

Concept

Your IP,

Our Support

Concept Raw Design

Product Sketches

Definition

From Design

to User Value

A-Surface treatment

Design

Best practices to create value in design

3D Detailed, CAD, DEM, DTC, DTV, DEMA

Prototyping

Pre-Production prototypes or small series

First Prototyping Production

Small Series

Validation

Robust Procedures for validation

Design Freeze for serial Production

Software

- Autodesk Moldflow / Moldex 3D (Rheology)

- Simcenter 3D / Femap (FEA analysis)

- Star-CCM+ / FloEFD (CFD)

- Siemens NX / Solid Edge / Catia (CAD)

Support Services

- Linear Statics

- Stress Fatigue

- Thermal fatige

- Vibration / Modal

- Computational Fluid Dynamics

- Rheology

Portfolio Across Innovative Industries

We partner with clients across diverse sectors, developing new products that demand advanced materials and methods. Our technologies enable flexible, tailored solutions, driving innovation and efficiency in every project.

AGRICULTURE

Design For

Manufacturing

DFM focuses on creating designs that simplify production and cut costs. By addressing manufacturing challenges early, it ensures efficiency, quality, and faster time to market.

INDUSTRY

Feasibility Process

Feasibility evaluates whether a project can be achieved within constraints like resources and costs. It reduces risks and lays a solid basis for seamless product development.

Shaping Concepts into Functional, Manufacturable Products

We support the full product design lifecycle, from initial concept to continuous improvement. Through a structured approach that integrates market insights, engineering expertise, and rapid prototyping, we turn ideas into manufacturable, high-performance solutions ready to scale with your business.

Optimised Production

We implement multi-material injection moulding, automated process controls, and micro-tooling to enhance precision, minimise cycle times, and maintain consistent quality standards.

Collaborative Development

Through real-time design iteration, material selection analysis, and prototype validation, we align technical feasibility with market demands, optimizing for performance and scalability.

Prototyping & Small-Scale Production

With advanced silicone moulding and 3D printing, we rapidly produce high-quality prototypes for design mockups or functional validation. We also support low-volume production of end-use parts, ideal for frequent design updates or cost-effective manufacturing.

Sustainable Processes

By integrating biodegradable polymers, lightweighting strategies, and closed-loop recycling, we optimize resource efficiency while ensuring compliance with international sustainability regulations.

Concept Development & Engineering Support

Early-stage validation through DFM (Design for Manufacturing), FEA (Finite Element Analysis), and material optimisation ensures product performance, cost-efficiency, and smooth integration into production, reducing risks and accelerating time-to-market.