Prototyping & Rapid Manufacturing for Better time-to-market

Validate Designs.

Accelerate Production.

Reduce Time-to-Market.

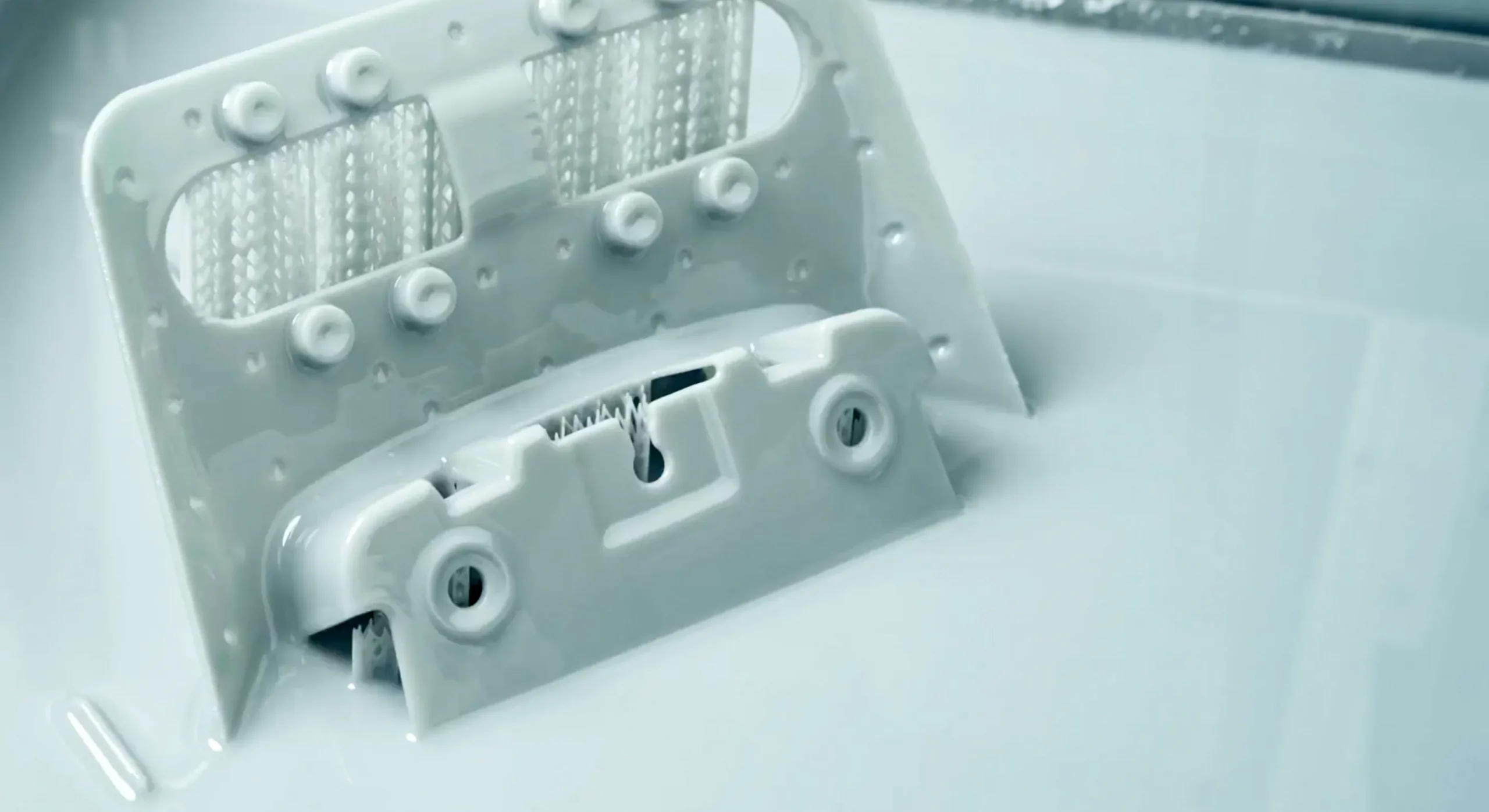

Prototyping validates your design through small-series production using silicone moulds and 3D printing, enabling precise adjustments before tooling. Rapid Manufacturing ensures fast delivery of low-volume, end-use parts, ideal for functional testing, iterations, or early market launch.

Test & Validation

Prototyping rigorously tests and refines product design, ensuring flawless aesthetics, functionality, and ergonomics. We craft diverse prototypes with transparent, textured, rigid, or flexible finishes.

Final Parts

Low-volume production suits small-scale needs, offering fast delivery and cost efficiency. It validates design and functionality, preventing issues and ensuring the final product meets all requirements.

From Functional Prototypes to Production-Ready Parts

Concept & Funcional

Validation

Prototyping checks your product’s design, perfect aesthetics, ergonomics and functionality. We identify and solve issues early to streamline production and save time.

Costumised and

out-of-stock Parts

Recreate discontinued or custom parts without expensive tooling. Rapid prototyping means precise adjustments and fast delivery to meet demands with tailored solutions.

Time-to-market

Products

Reduce risk, save costs and speed up launches with rapid prototyping. Adapt to market demands and refine designs to get to market faster and more efficiently.

Large Parts &

Small Series

For small series or large polymer parts, rapid manufacturing ensures high quality production with fast delivery and cost savings. Perfect for prototypes or real use.

Prototyping & Rapid Manufacturing Experts

We develop products that demand advanced materials and prototyping techniques. Our technologies enable fast, tailored solutions for diverse industries, driving innovation and efficiency.

Prototyping

Quickly test and validate concepts, reducing costs and accelerating the development of innovative products, such as electric or hybrid vehicles, which require complex geometries and advanced materials.

Small Series

Flexibility and rapid response to specific market needs, such as producing customised models and testing new technologies that can enhance vehicle performance without compromising quality or safety.

Specialised Prototyping and Manufacturing for Evolving Needs

We apply advanced prototyping and rapid manufacturing techniques to turn concepts into functional, market-ready products. Our streamlined process reduces development time, supports design iterations, and ensures flexibility to meet evolving industrial requirements.

Rapid Response Manufacturing

We offer on-demand production for urgent needs, ensuring fast turnaround for replacement parts, tooling, and critical components when supply chain disruptions occur.

High-Mix, Low-Volume Flexibility

Our versatile production setup allows for small to medium batch manufacturing, perfect for specialised industries that require frequent design updates or limited-series production.

Advanced Surface Finishing & Customisation

We provide textured surfaces, precision coatings, and multi-material bonding to enhance durability, aesthetics, and performance of final parts.

Sustainable Manufacturing

We incorporate recyclable materials, energy-efficient production processes, and closed-loop systems, ensuring sustainability without compromising quality.

Customisation and Complexity

Producing parts with diverse materials, finishes, and complex geometries, whether small or large in size, becomes a viable and economical option, even for limited productions, overcoming the limitations of conventional manufacturing methods.