Engineering Thermoplastic Injection Moulding Excellence

Injection Moulding Built for Industrial Performance

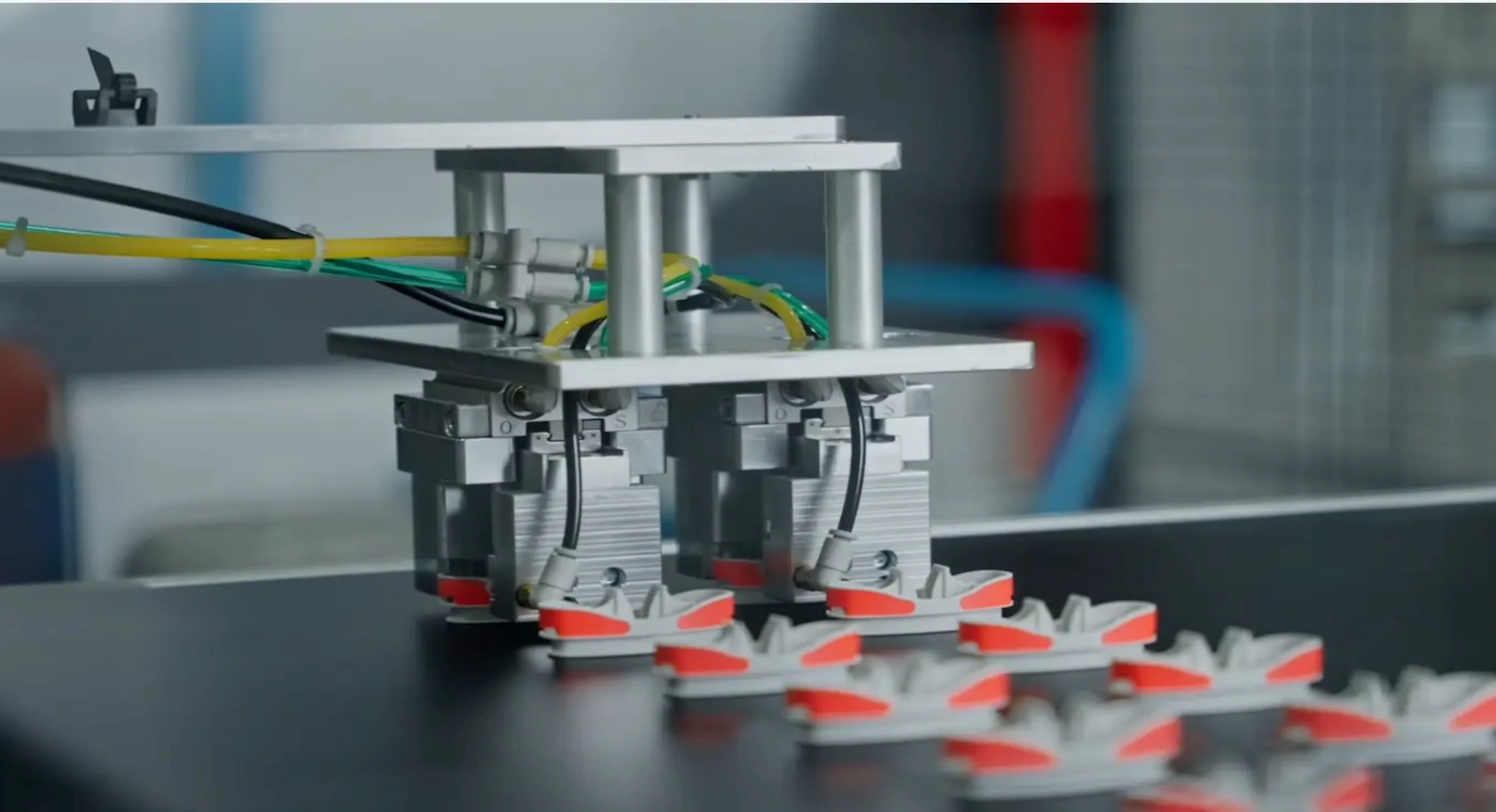

For each product, we integrate advanced automation in the thermoplastic injection and assembly processes, supported by artificial vision systems that guarantee 100% quality control. With exceptional production efficiency and optimised material usage, our injection moulding process is cost-effective, integrating multiple features into a single cycle and reducing the need for costly, time-consuming assemblies.

Quality Control

Certified to IATF 16949 and ISO 9001, our quality system complies with the highest international standards for process control and product reliability.

We apply advanced metrology and rigorous inspection procedures to ensure dimensional accuracy and repeatability in every production batch.

24/7 Production

Our manufacturing cells run 24/7, combining electric injection moulding machines with automation and quality control systems.

This enables high productivity, reduced downtime, and consistent part quality across all shifts.

Injection Moulding Built for Industrial Performance

MES: Manufacturing Execution System

Our MES (Manufacturing Execution System) monitors every step of plastic parts production, ensuring full traceability, reduced waste, consistent quality, and accurate delivery forecasts.

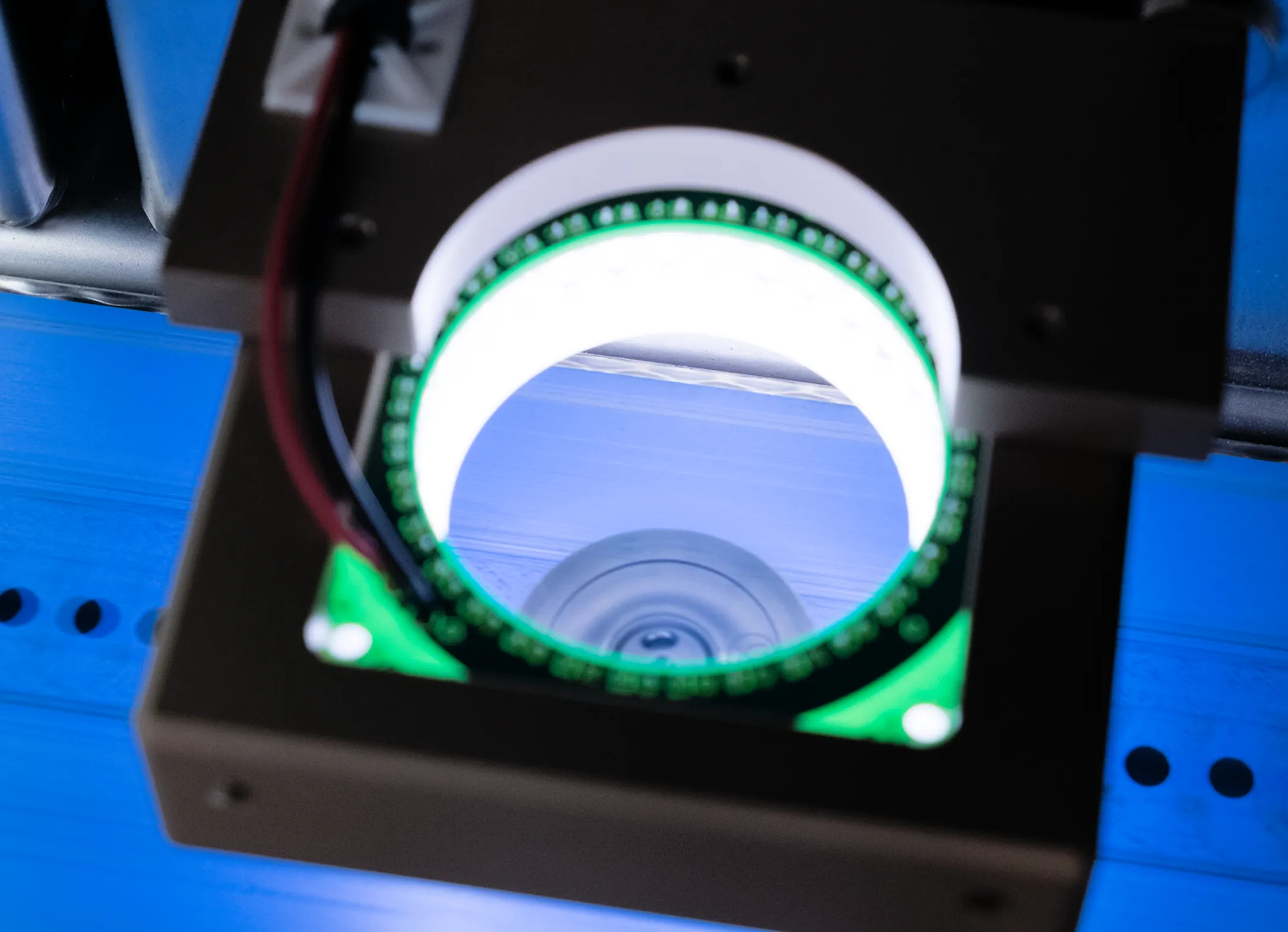

In-Line Visual Inspection Systems

Integrated camera systems perform real-time defect detection directly on the moulding line. These automated inspections ensure 100% part verification, immediate feedback, and full traceability

Three Levels of Quality Control

We ensure precision with CMM measurement, real-time vision monitoring, and automated defect detection, guaranteeing consistency, reduced waste, and cost efficiency.

Full Process

Traceability

Covering the entire supply chain to identify issues early and drive improvements. From raw material selection to final inspection, we ensure optimised quality.

Technology-Driven. People-Led. Results-Focused.

Experience across multiple industrial sectors

We work across multiple industrial sectors, delivering technical solutions for products with stringent requirements in materials, processes, and validation. The reliability of our work stems from the experience and commitment of our teams. Supported by adaptable technologies, we ensure precise and efficient results for industries that demand innovation and consistency.

2K/3K Injection Moulding

Our expertise includes chemical and mechanical bonding, rotary platen and index plate systems, transfer and core-back technologies, ensuring high precision and performance for demanding applications.

Large Moulds & Special Materials

Designed for demanding industrial applications, our moulding capabilities reach up to 23000 tons, combining high-performance materials such as PEEK and PVCU to ensure durability, precision, and superior performance.

Your Process, Fully Controlled and Delivered

We combine advanced injection moulding processes, full traceability, and strict quality controls to guarantee consistent output and timely delivery. With real-time oversight and project-focused execution, we help you meet your goals with confidence and peace of mind.

Product Traceability

We monitor every step of production, ensuring you are always updated on your product’s status, from start to finish, for complete peace of mind.

On-Time Delivery Planning

Our secure planning process ensures we meet deadlines, optimising each phase of production so that your project is always delivered on time.

Sustainability in Production

Our energy-efficient facilities, powered by solar panels, aim for self-sufficient energy consumption, ensuring sustainability while maintaining high production standards.

Dedicated Expertise Teams

Specialised teams for each industry provide tailored solutions, ensuring your project aligns with your vision and receives the support needed for success.

Comprehensive Project Management

We are customer dedicated. By maintaining open communication, we ensure your project stays on track, increasing efficiency and delivering top-quality results.