- Autodesk Moldflow / Moldex 3D (Rheology)

- Simcenter 3D / Femap (FEA analysis)

- Star-CCM+ / FloEFD (CFD)

- Siemens NX / Solid Edge / Catia (CAD)

Your global partner for plastic solutions

Global leaders in plastic product and tooling development.

VANGEST in Numbers

39 Years of

Experience

Experience takes time.

350+ Experts

Worldwide

People Moulding the future.

Industrial

Capacity

Extensive technology facilities.

Worldwide

Presence

Integrated teams across 4 countries.

Our Vision, Mission & Values

Vision

Through our People become a world leader in injection mould and moulding related services.

Mission

Offering our customers PREMIUM engineering services, high-quality moulds, and moulding at the most competitive prices.

Values

WE Team up!

WE, instead of ME.

WE share knowledge.

WE are all customer ambassadors.

WE respect each other.

WE care for the health and safety of all.

WE recognise performance.

For every stage of your product lifecycle

From startups to global companies, we bring expertise and scalable solutions to propel your project forward. Every stage of your product’s lifecycle matters to us. We are here to ensure your success, every step of the way, moulding life’s motion.

Concept

Product Development

Industrialisation

Concept

Your IP,

Our Support

Concept Raw Design

Product Sketches

Design

Best practices to create value in design

3D Detailed, CAD, DEM, DTC, DTV, DEMA

Prototyping

Pre-Production prototypes or small series

First Prototyping Production

Small Series

Validation

Robust Procedures for validation

Design Freeze for serial Production

Project

Accurate Project Management

Tooling, Design DFM for Tooling Process & Product Validation

Production

Tooling, Injection & Assembly

ISO7

Cleanroom production

Automated assembly

Artificial vision inspection

Logistics expertise

Software

Support Services

- Linear Statics

- Stress Fatigue

- Thermal fatige

- Vibration / Modal

- Computational Fluid Dynamics

- Rheology

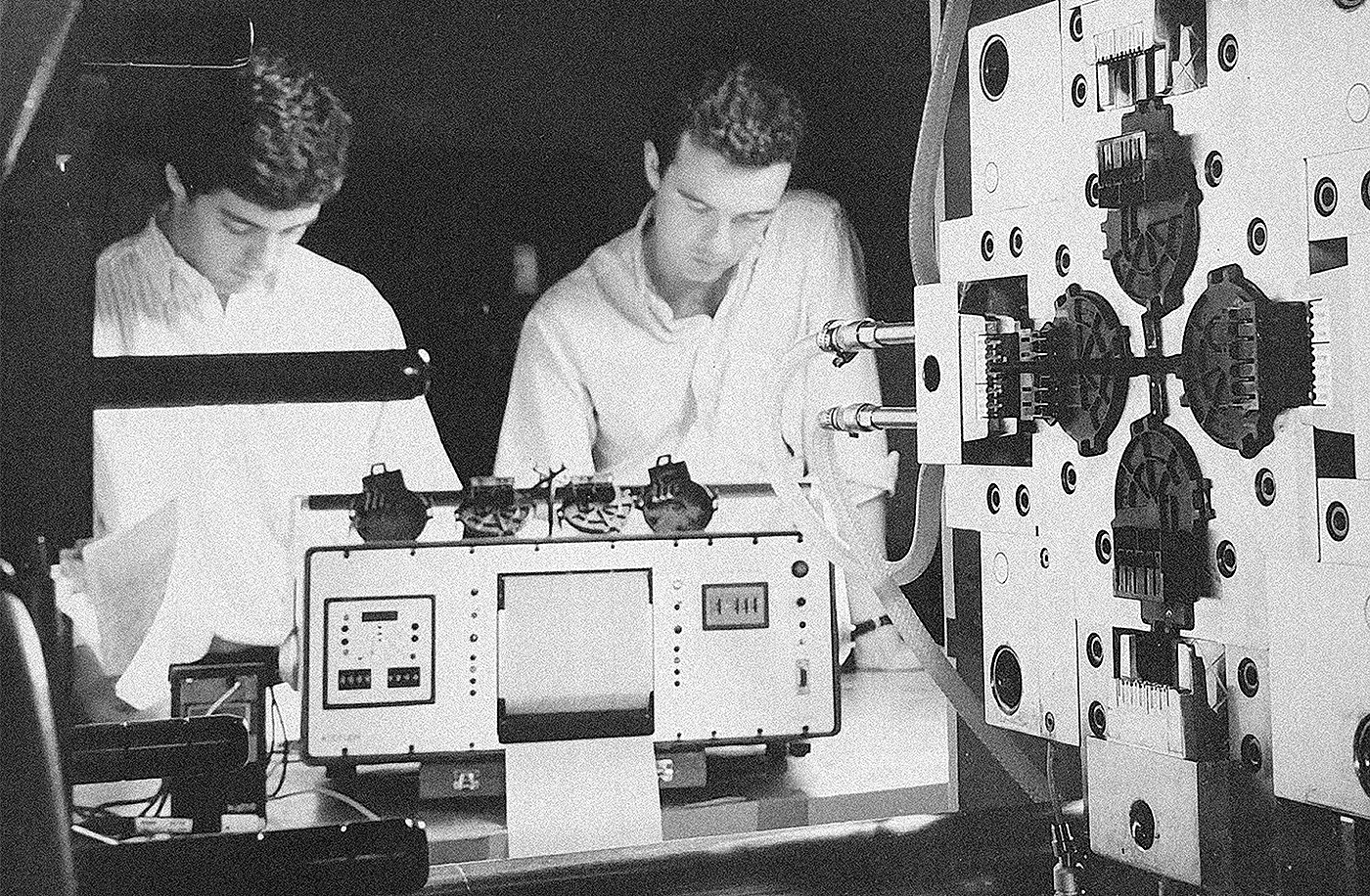

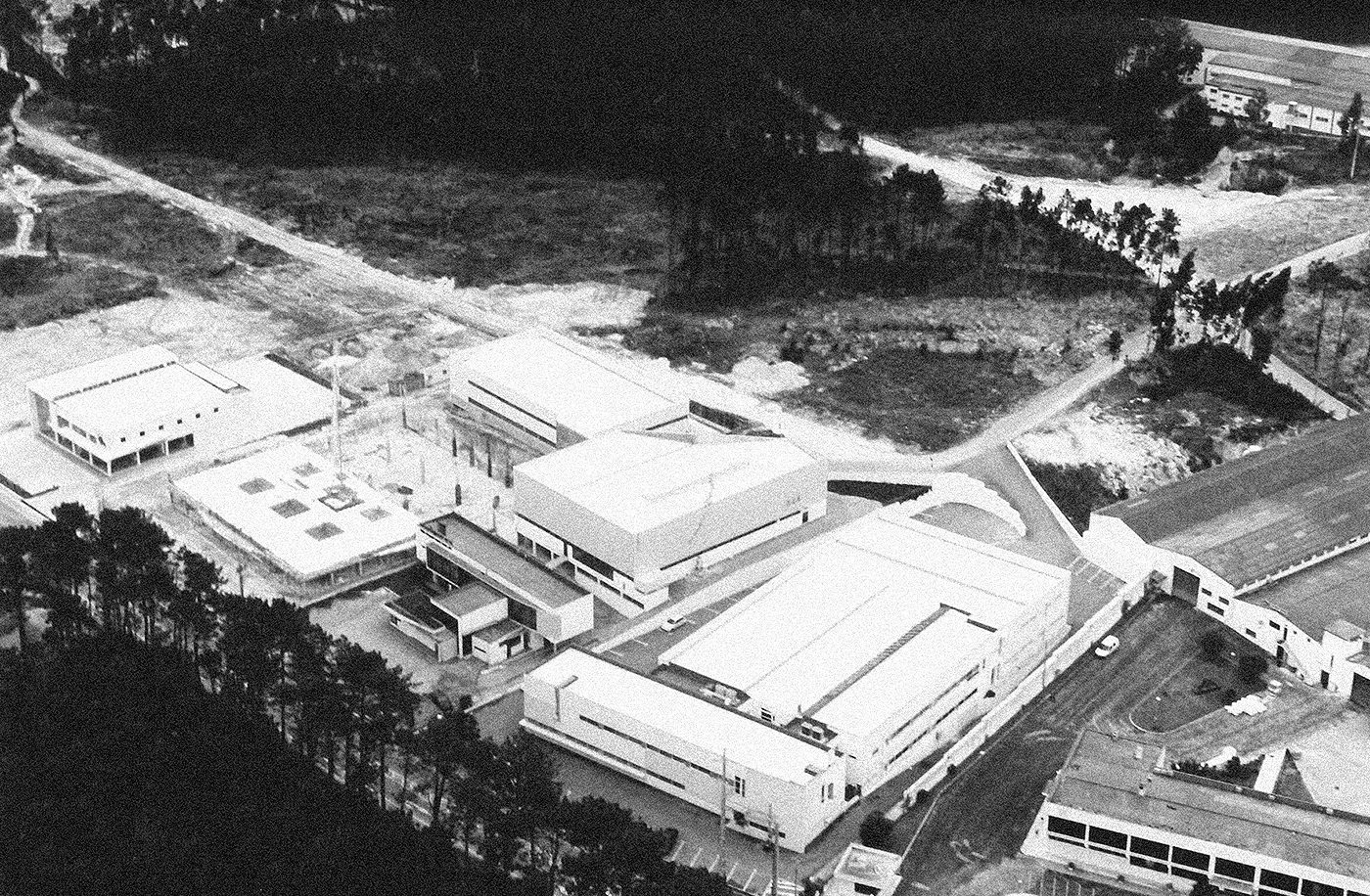

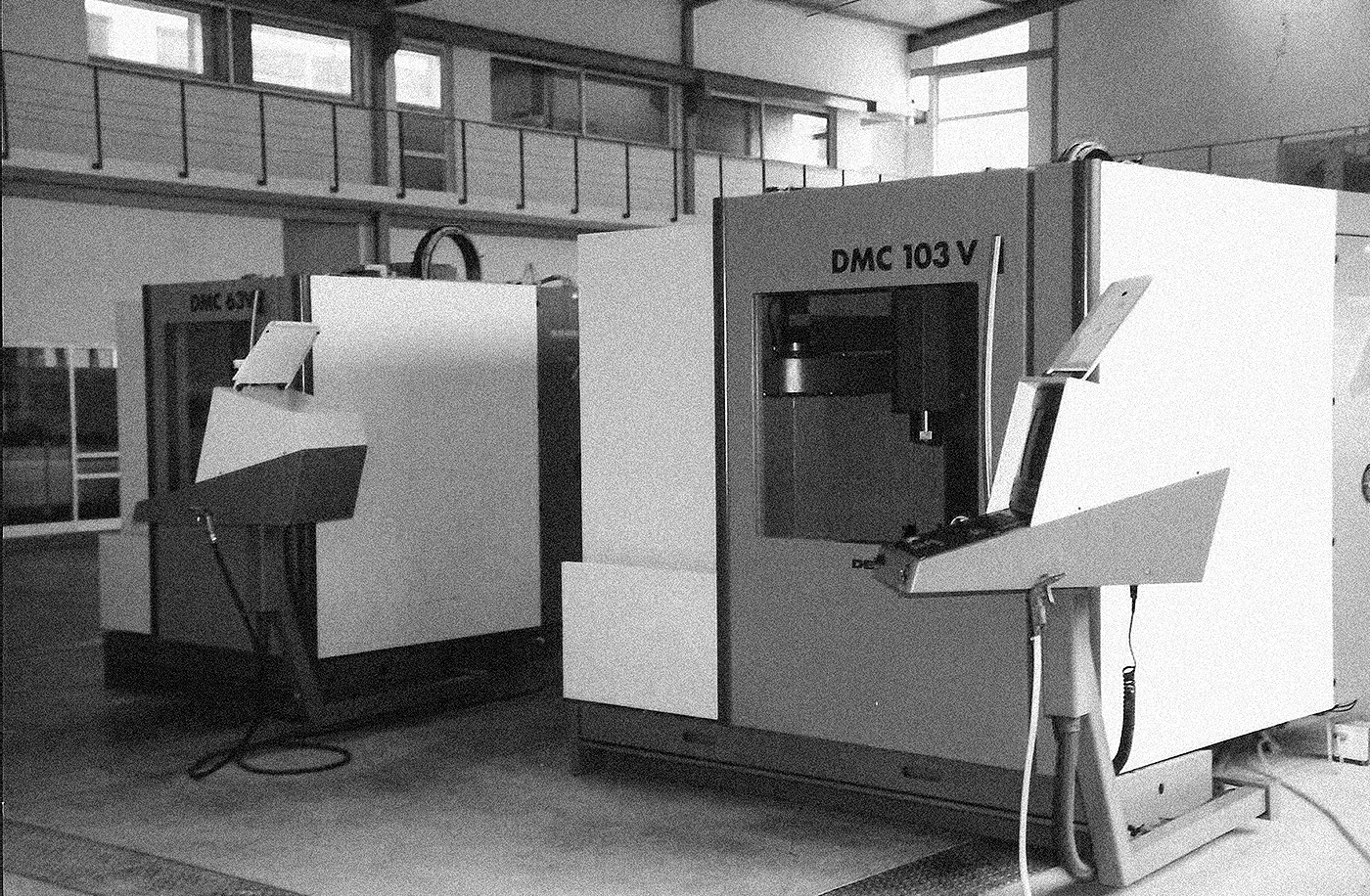

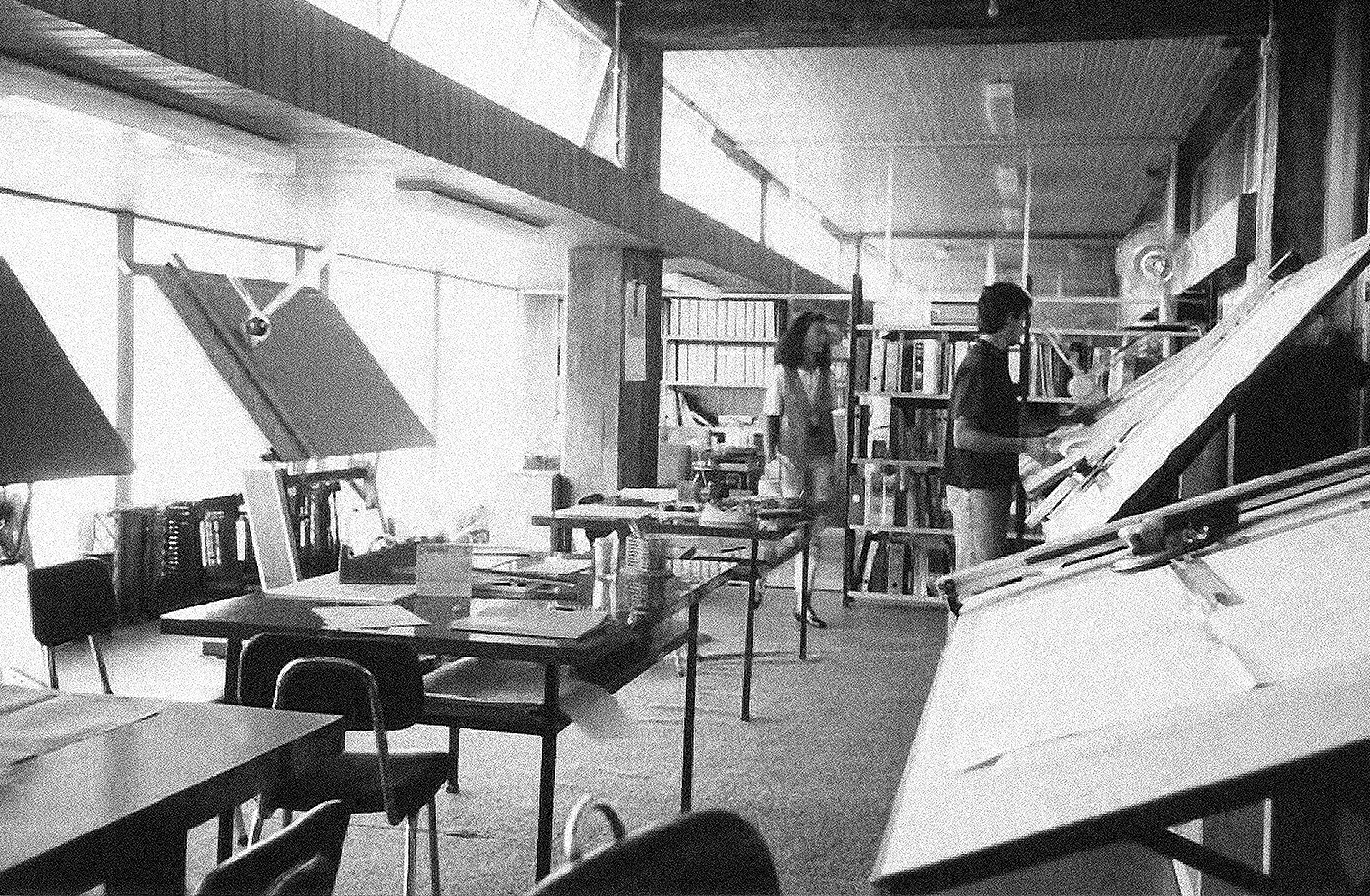

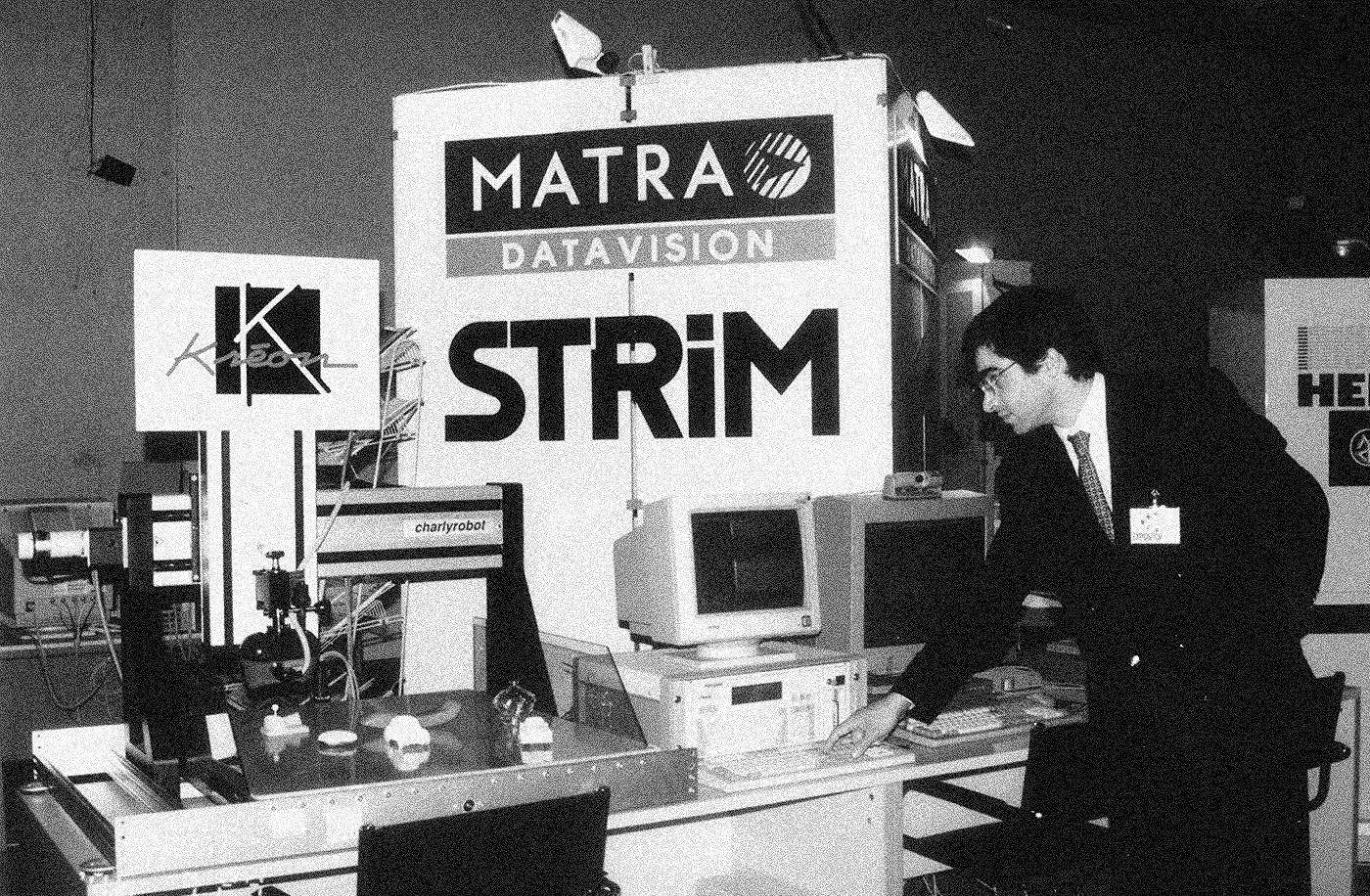

Our Facilities & Equipments

With a combined footprint that spans thousands of square meters, we operate as a unified structure, where each site contributes specialised capabilities, from precision mould making and high-tech injection moulding to metrology, automation and beyond.

People & Culture

Our People are the heartbeat of our success. Their dedication and expertise form the foundation on which we thrive. We nurture talent and encourage creativity. Shape the future with us, moulding life's motion.

Governance

Structure

Governance

The Executive Committee leads VANGEST’s operations, reporting directly to the Board of Directors. It ensures strategic alignment, operational excellence, and sustainable growth while driving key decisions on resources and compliance.

Board Members

Meet the leadership driving our vision. Our Board combines experience, strategy, and innovation to guide the VANGEST’s success and sustainable growth.

Innovation & Sustainability

Committed to a sustainable future, we take responsibility for innovating and for implementing eco-friendly industrial practices. Discover how we are making a positive impact on our planet and communities.

3084 T

Solar Energy Produced

by 100 Solar Panels

6106 MWh

CO2 Pollution

Prevented

268 084

Coal Consumption

Avoided