With a dedicated production unit in Portugal and a technical support team based in Barcelona, we ensure consistently high quality and swift responses to client needs worldwide. This synergy of local manufacturing expertise and specialized support allows us to deliver comprehensive solutions on a global scale.

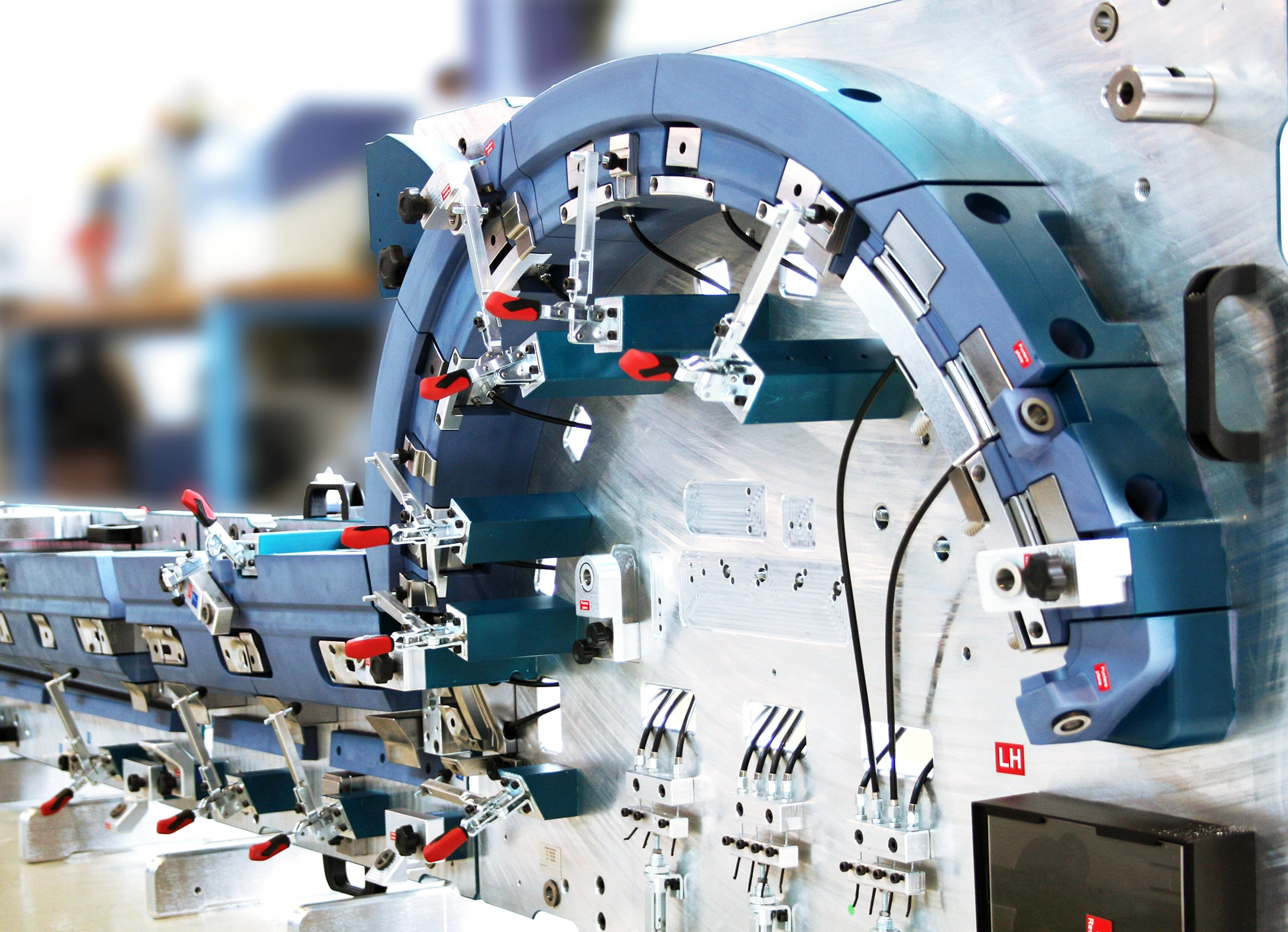

Checking Fixtures for Automotive Industry

Custom-engineered to validate complex geometries with precision and ease of use.

We have an extensive portfolio for Checking Fixtures

We collaborate with clients from diverse industries, working on a wide array of products that require various materials and prototyping techniques. Our technologies provide us with the flexibility to devise creative solutions for industries that prioritise innovation and efficiency.

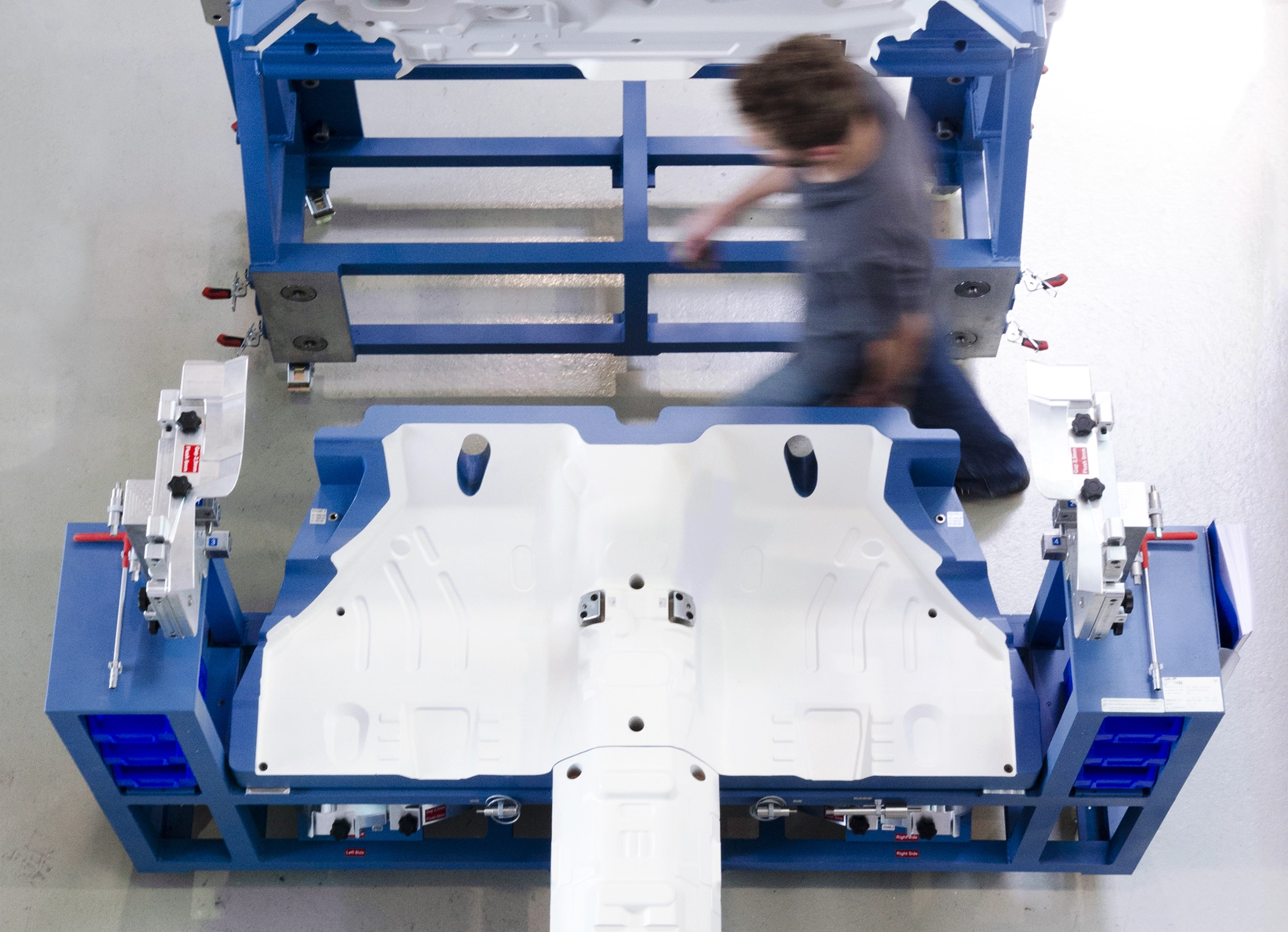

Cubing

Cubing or Meisterbock Cubing to analise actual behaviour of the parts in real car assembly conditions.

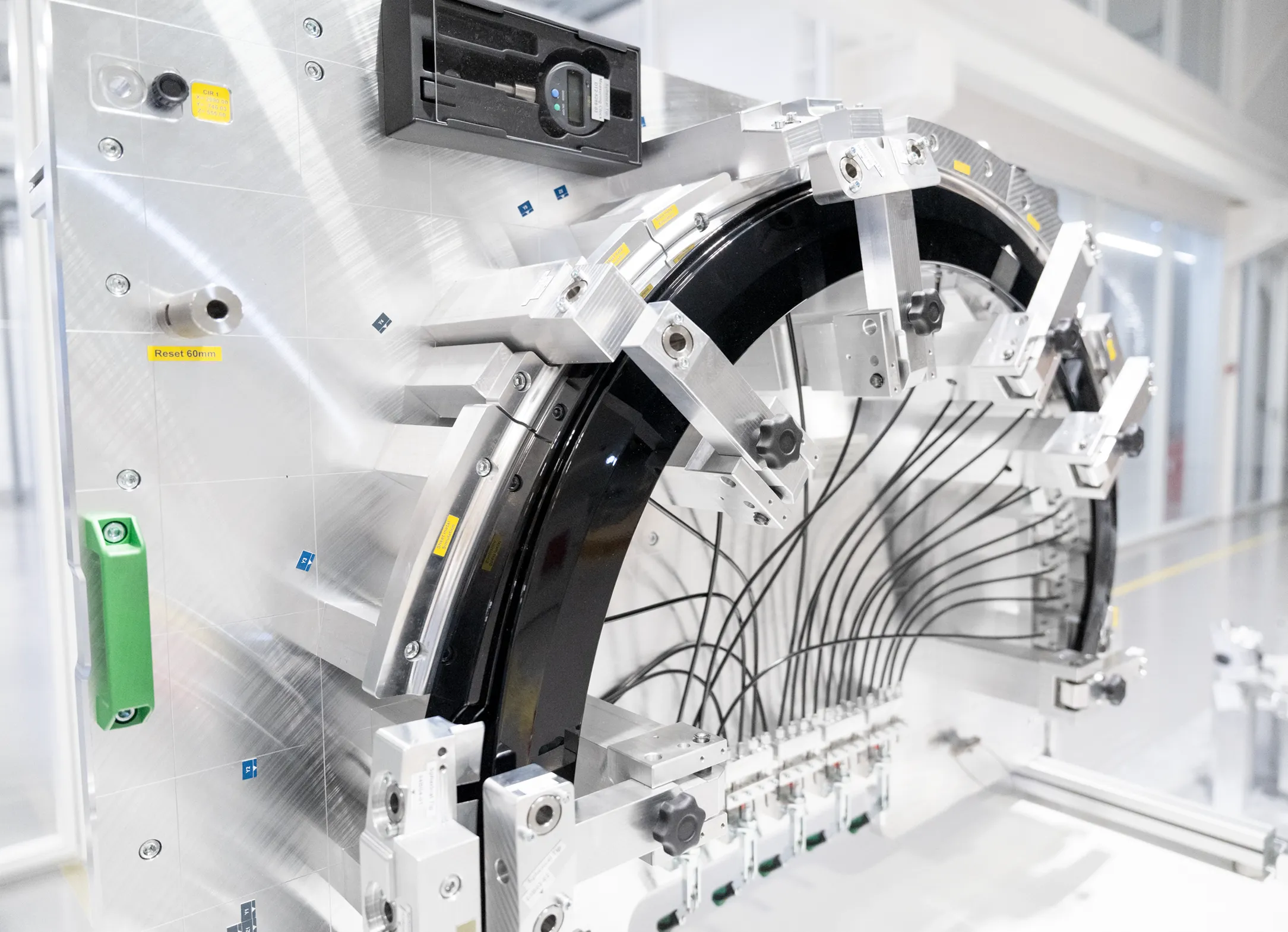

Automated Checking Fixtures

Smart fixtures incorporating technology (laser systems, pneumatic probes, visual aid) to improve process productivity.

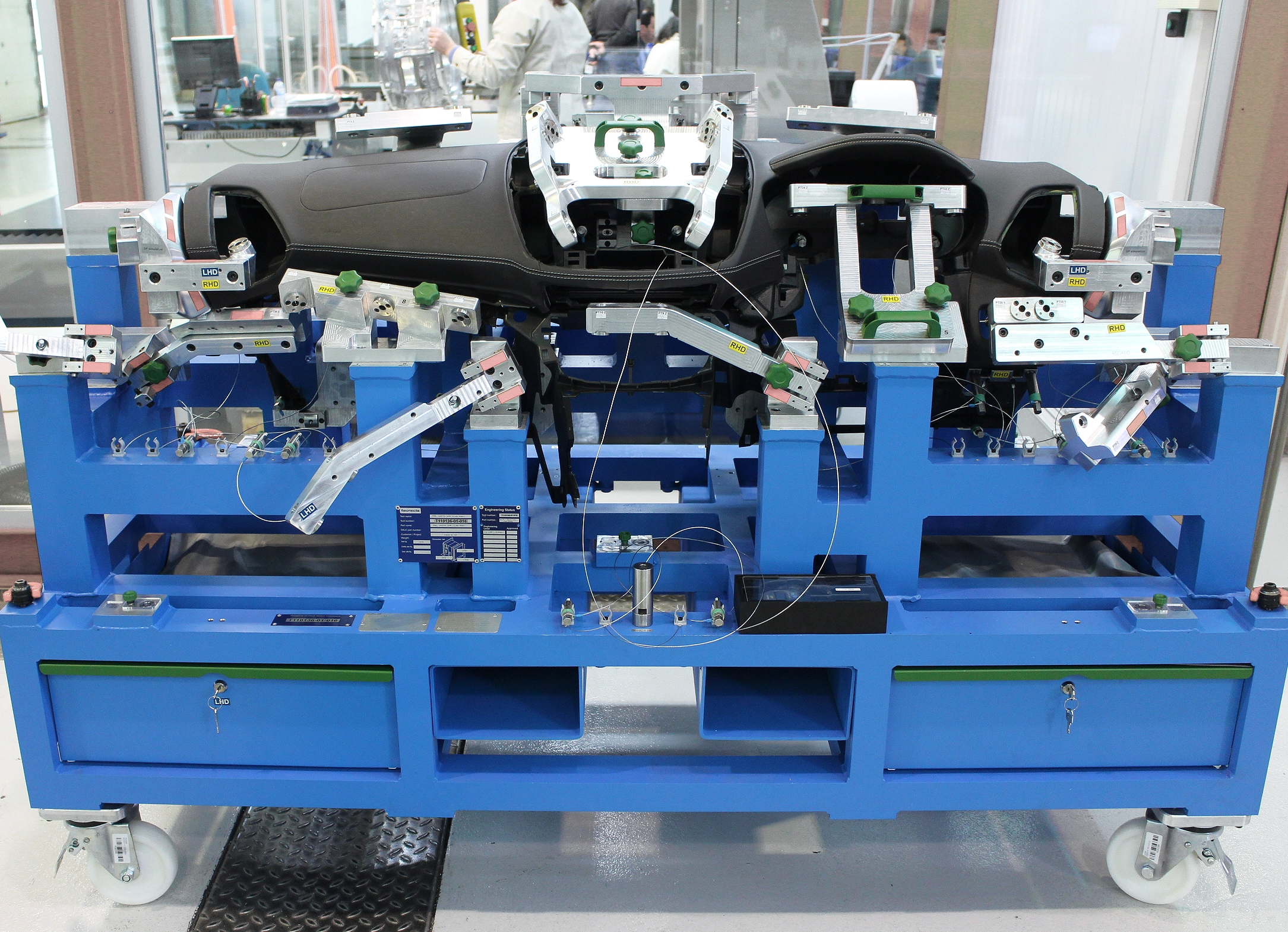

Interior Parts

For dimensional control by volume reproduction, gap and flush, clipping mechanisms and/or statistical process control.

Exterior Parts

Gauges including tools with special emphasis on making sure not to damage the parts.

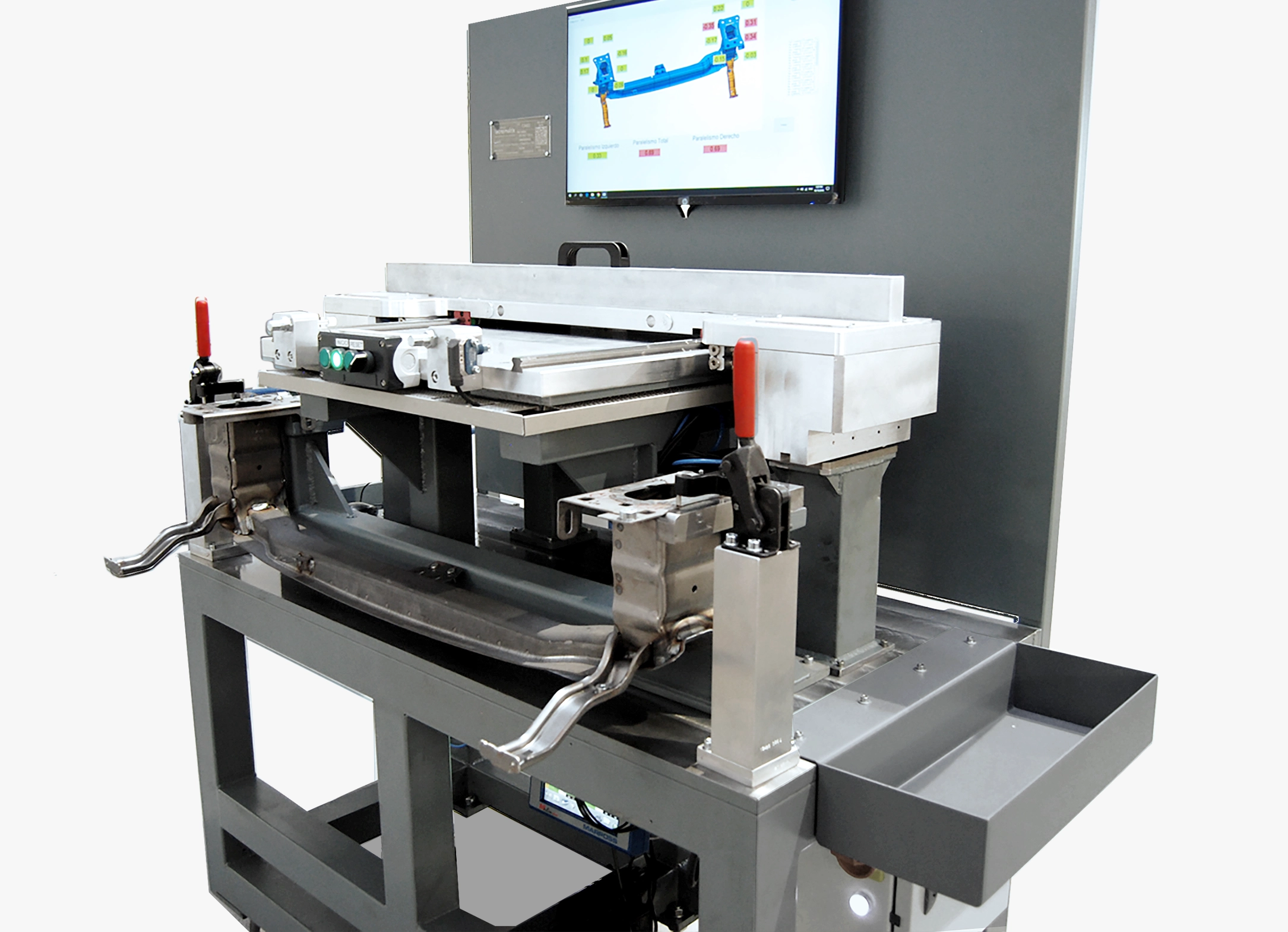

Metal Parts

Control fixtures, positioners, stonning bucks with wide variety of materials of construction.

Assembly Fixtures

Commonly used for the Tier 1 to check their individual parts as well as what the OEM will analise after assembly.

Trusted Partner in Dimensional Validation

+ 27 years of experience

For more than two decades, we have been working with industries that require intricate and complex component shapes due to the advanced designs and functionalities of their products.

Facilities &

Equipments

With energy efficient processes in place, our best-in-class CNC 5-axis machines and autonomous manufacturing systems deliver accurate results, even for the most complex geometric parts.

Metrology & Quality Control

Through digital measuring systems, such as our state-of-the-art CMM machines, deviations can be promptly determined to ensure that parts adhere to dimensional and positioning tolerances.

Certificated

Expertise

Specialised facilities with dedicated technologies and resources allows us to develop focused expertise and optimised processes.

Where Expertise, Capacity and Precision Converge

We bring together specialised teams, strategic locations, and extensive production capabilities to deliver precise, high-quality solutions for our clients. Our expert workforce collaborates closely with you at every stage, ensuring on-time delivery and consistent excellence.

Positioned Near Key Industry Clusters

We operate in close proximity to a major European industrial ecosystem, enabling rapid collaboration, agile supply chains, and immediate access to advanced technological resources.

Robust Checking Fixtures Production Capabilities

We produce over 500 checking fixtures each year, ensuring an extensive selection to address evolving industry demands. By continually refining our processes and expanding our capabilities, we deliver reliable, high-quality solutions that meet a wide range of client requirements.

Expert Workforce

With 60 specialists dedicated to checking fixtures production and 14 experienced design engineers, our team combines technical expertise with innovative thinking to deliver precise, high-quality solutions.

Tailored Solutions & On-Time Delivery

From concept to completion, we collaborate closely with you, ensuring each project meets strict deadlines without compromising on performance or reliability.