Medical Plastic Solutions for a Healthier Tomorrow

Precision Plastic Manufacturing for Medtech, Pharma & Biotech.

We help medical innovators accelerate time-to-market with fully integrated plastic engineering, in-house validated production, and ISO 13485 compliance. Our solutions ensure total lifecycle traceability and full regulatory alignment.

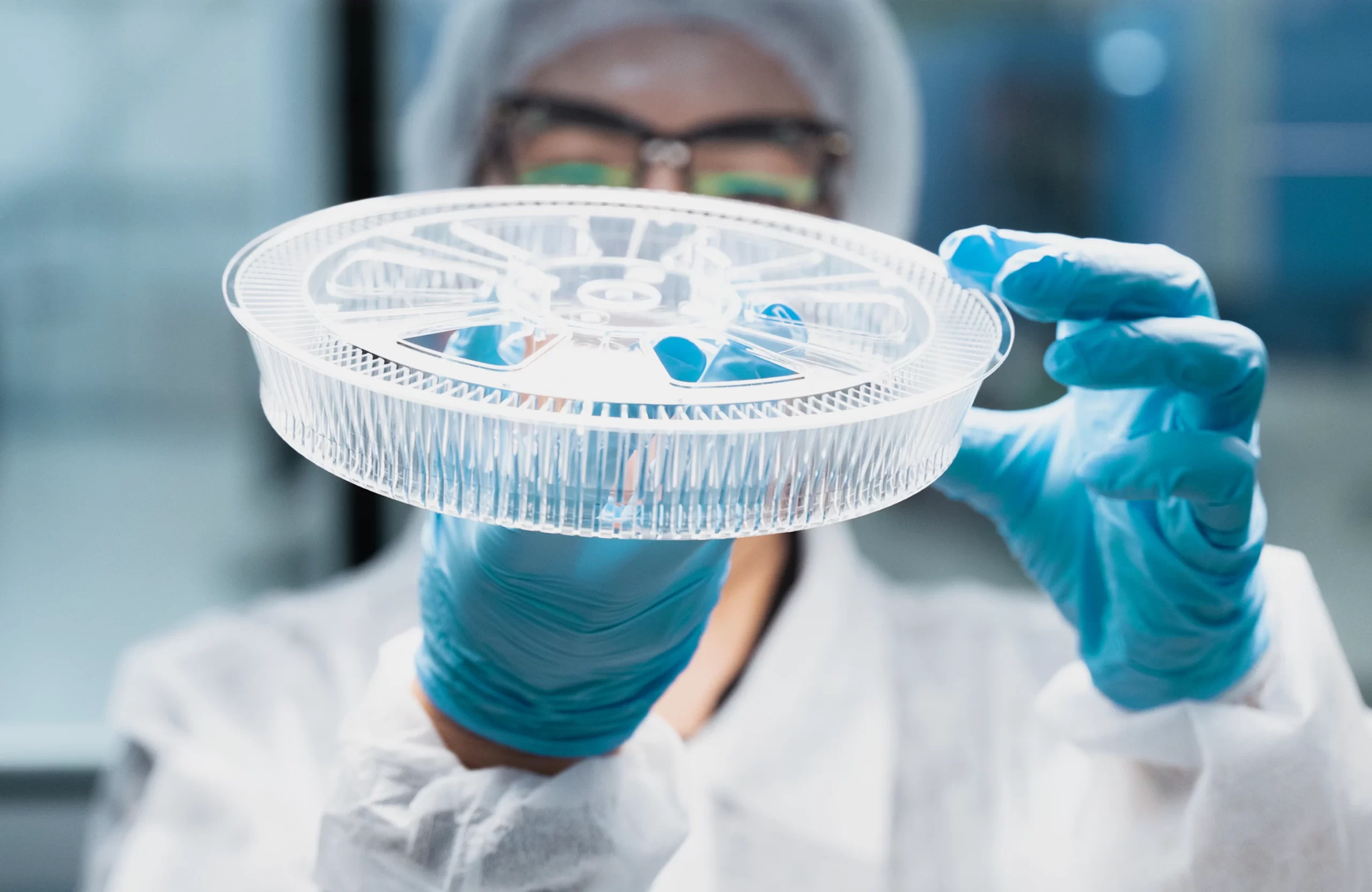

Devices

From precision tooling to validated moulding, we manufacture devices for lifecycle compliance and seamless integration into ISO 13485-certified production systems.

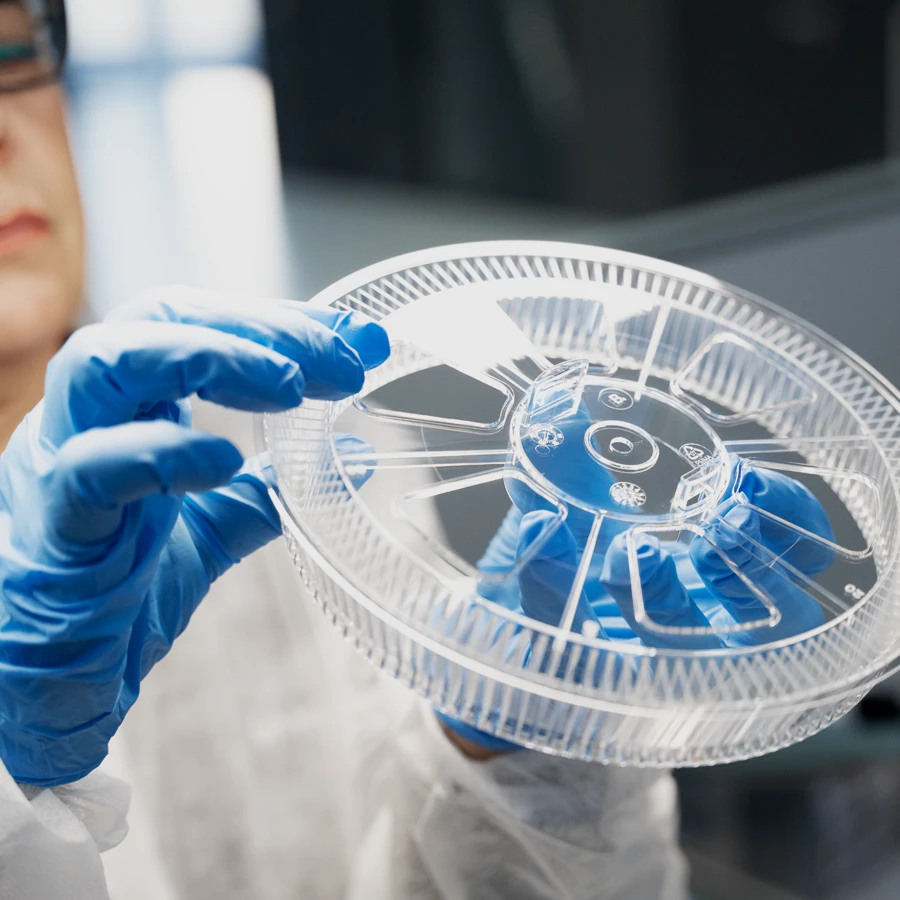

Diagnostics

We engineer dimensionally critical diagnostic parts with in-house DFM, advanced tooling, and cleanroom injection, ensuring sterility, accuracy, and process validation.

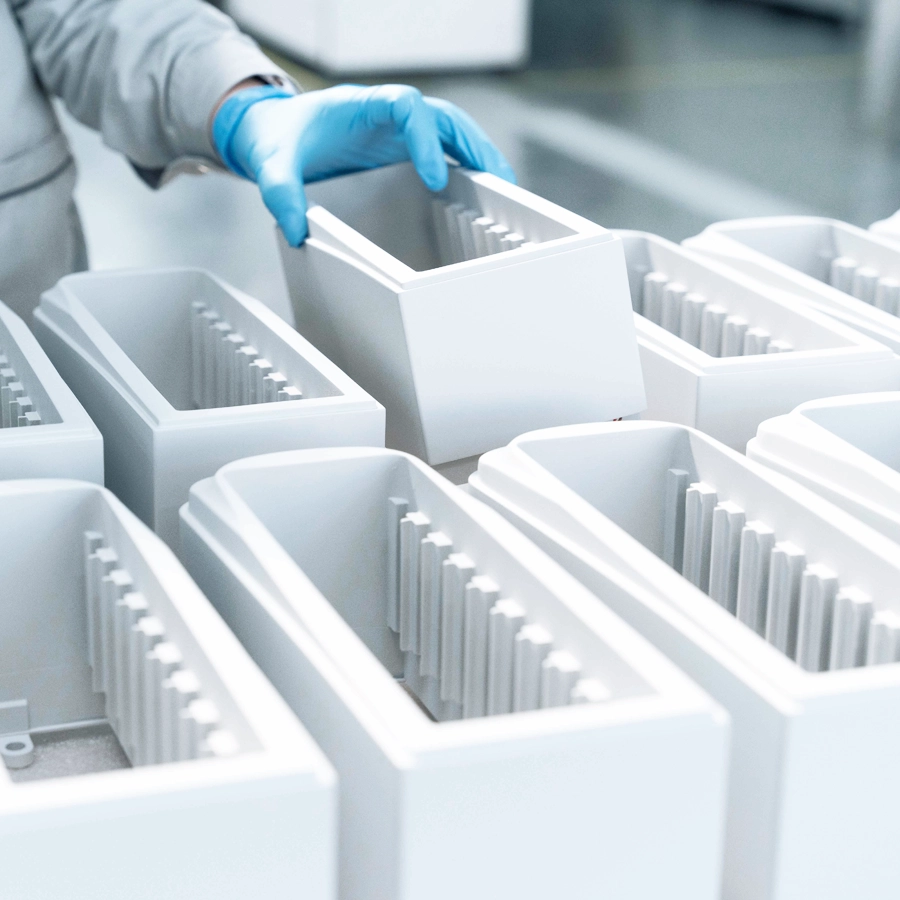

Consumables

We manufacture consumables for high repeatability and cost-efficiency, with ISO 7 cleanroom assembly capabilities for pharma, biotech, and clinical use.

Integrated Plastic Solutions

End-to-End Manufacturing Partner for Certified Medical Products

We deliver fully integrated engineering, mould making, and ISO 13485-certified injection moulding, with robust validation and cleanroom capabilities tailored to the demands of regulated medical markets.

Full Product Lifecycle Integration

From concept to validated production, we streamline every step to reduce risk and accelerate readiness.

Regulatory-Compliant and Validated Manufacturing

Our manufacturing model is built on strict process validation (DQ, IQ, OQ, PQ), risk mitigation (DOE, FMEA), and cleanroom ISO 7 production, ensuring that every product meets global regulatory requirements and quality assurance standards for medical devices.

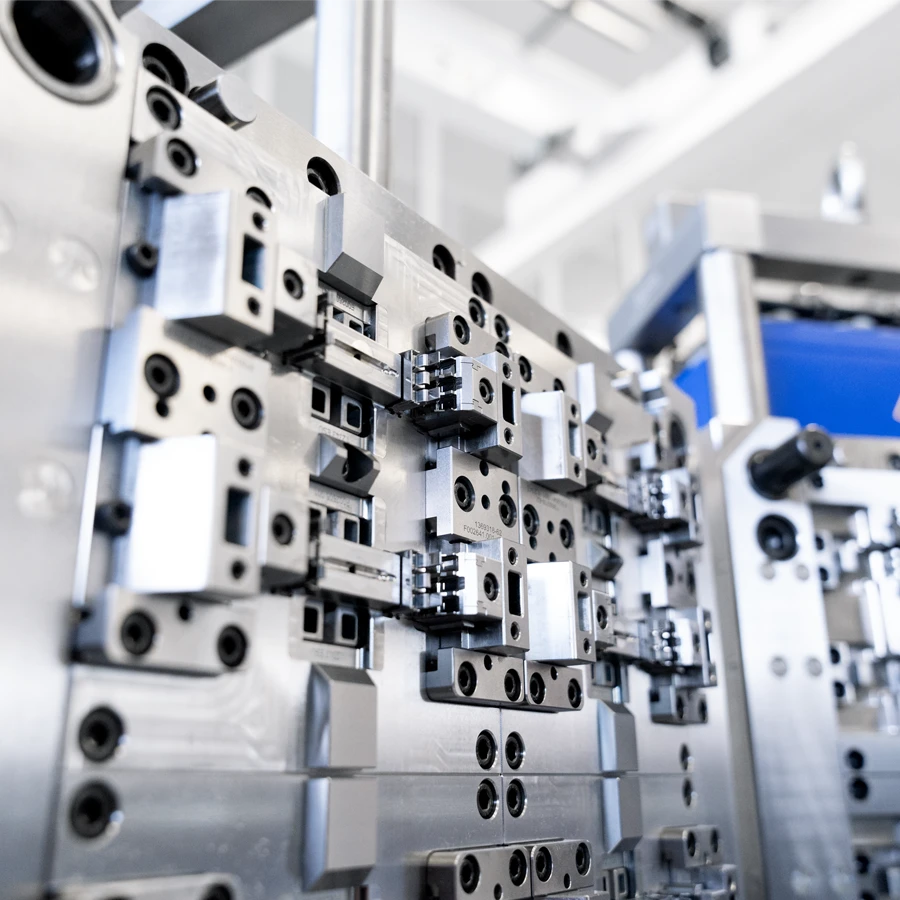

Advanced Mould Making and Injection Expertise

With decades of precision tooling and injection moulding experience, we deliver complex, high-tolerance components ready for scalable medical production. Our in-house capabilities ensure robust tool performance, dimensional stability, and repeatability in high-volume output.

Balanced Costs and Value through Design Optimisation

We apply DFM, DTC, DFA, and DTV principles to optimise manufacturability and cost without compromising quality.

Engineering with Simulation-Driven Decision Making

CAD, FEA, CFD, and Moldflow tools drive early-stage decisions that reduce iterations and improve long-term yield.