Injection Moulding Engineered for Precision

Cleanroom ISO-7 Injection Moulding

Our ISO 7 cleanroom integrates high-performance injection moulding cells engineered for validated medtech production. The environment is fully monitored for air purity, microbial load, and particulate control, ensuring ISO 13485 compliance, traceability, and cleanroom transfer readiness from first shot to scale-up.

ISO-7 Cleanroom Injection Moulding

We manufacture Class I and II medical components in ISO Class 7 cleanroom environments, following validated IQ/OQ/PQ protocols and ensuring fully traceable documentation. All tooling is qualified for cleanroom transfer, material compatibility, and sterility assurance at every stage.

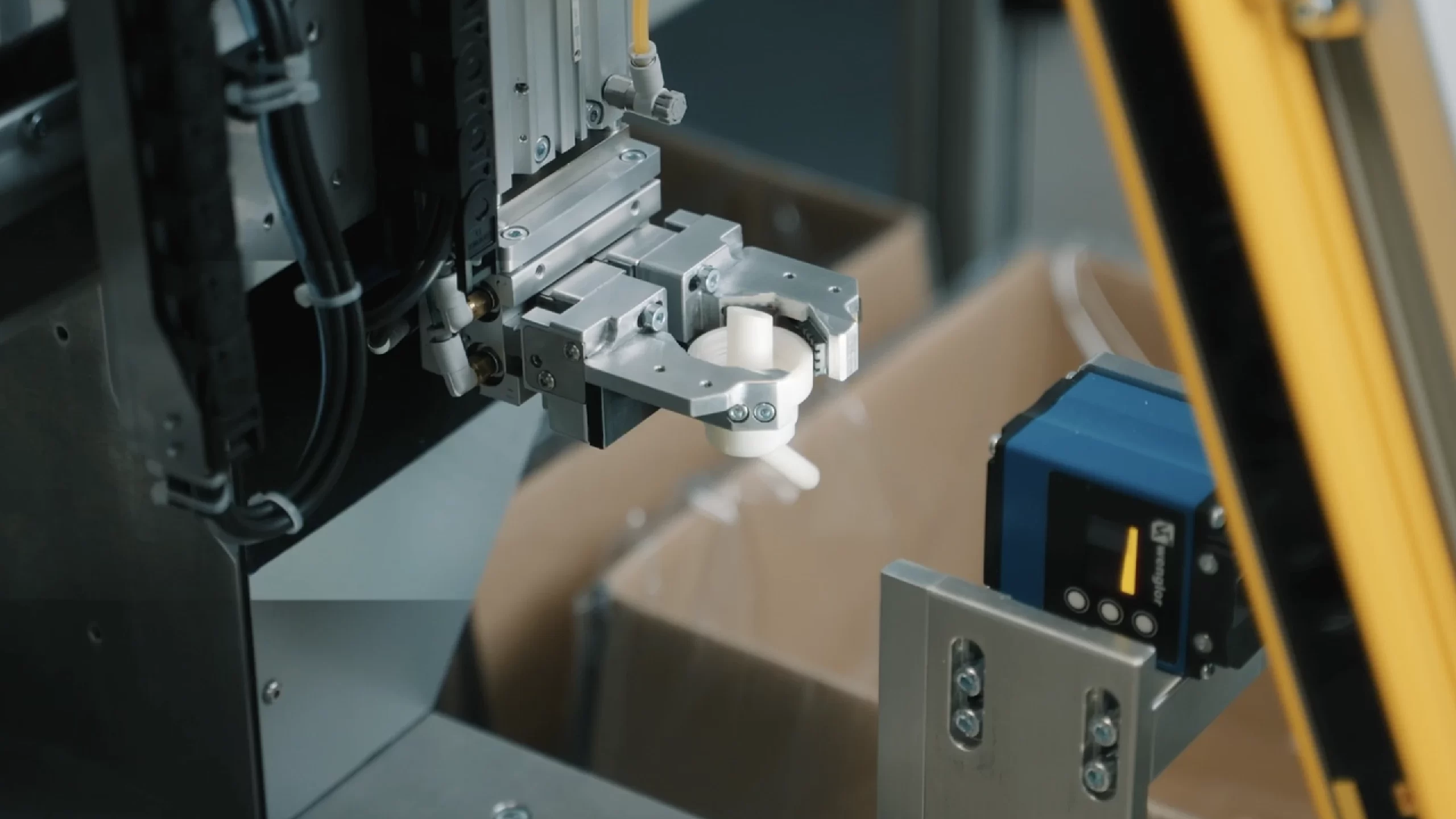

Automated Process

We deploy fully automated moulding cells combining robotics, servo-electric injection, cavity pressure sensors, and closed-loop process control. Designed for medtech scale-up, this system ensures statistical repeatability and fast cycles.

Our Injection Moulding Process for Medical, Lab & Healthcare

Process & Product Validation

Our injection moulding processes are built for full regulatory traceability and aligned with Good Manufacturing Practices (GMP). From design qualification to scale-up, each product undergoes a rigorous validation path.

1. DQ

Design Qualification

2. FAT

Factory Acceptance Test

3. MTV

Mould Validation Validation Protocol

4. IQ

Instalation Qualification

5. PD

Process Development with Design Experiments

6. OQ

Operational Qualification

7. PQ

Process Qualification

8. SOP

Start of Production with validated protocols

Advanced Injection Moulding for Functional Integration

We integrate functionality during moulding to eliminate secondary operations and streamline compliance. From overmoulding and in-mould labelling to embedded sensors, each process is controlled by scientific moulding protocols and executed in ISO 7 environments. The result: validated, traceable, and cleanroom-ready components, produced with repeatability and regulatory alignment.

Scientific Moulding Approach

Every injection moulding cycle is governed by scientific moulding principles, including cavity pressure profiling, gate freeze detection, and integrated vision systems for defect detection and traceability. This approach supports statistical process control and contamination-free compliance for medtech applications.

White Room for Assembly

Secondary operations such as overmoulding, label application and the assembly of electronic components, including sensors, are carried out in white room environments. These controlled spaces support microbial compliance, process stability and full traceability for components intended for use in Class I and II medical devices.

Functional Moulding

Integration

We engineer parts to minimise assembly and streamline functionality. Whether through insert moulding, in-mould labelling, or integrated sealing, our approach reduces downstream operations and boosts performance directly from the injection moulding machines.

Medical Injection Moulding Designed for Performance

From prototyping to large-scale production, we deliver certified injection moulding solutions tailored to medical requirements. Count on process stability, high-performance materials, and consistent quality across every component.

High-Precision Medical Parts

Micron-level dimensional control for critical components, connectors, and drug-delivery interfaces.

Scalability for High-Volume Production

We offer cost-effective, high-volume production of medical devices using injection moulding, ensuring consistent quality and efficiency across large-scale manufacturing.

Biocompatible Materials

We use a wide range of medical-grade polymers selected for their biocompatibility, chemical resistance and durability, making them suitable for various healthcare applications.

Highly skilled and dedicated teams

Our expert team, specialised in medical injection moulding, transforms complex challenges into innovative, tailor-made solutions, consistently exceeding the highest industry standards.

Fully Customised Solutions

Application-driven injection strategies tailored for functionality, sterility, and regulatory fit.